What Type Of Mixture Is Steel

News Leon

Mar 29, 2025 · 6 min read

Table of Contents

What Type of Mixture is Steel? Exploring the Metallurgy of Alloys

Steel, a ubiquitous material shaping our modern world, is far more than just a simple mixture. Understanding its nature requires delving into the fascinating realm of metallurgy and the science of alloys. This comprehensive article explores the intricate composition and properties of steel, clarifying its classification as a homogeneous mixture, and examining the factors that influence its diverse applications.

Steel: A Homogeneous Mixture of Iron and Carbon

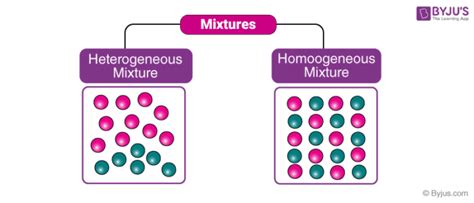

At its core, steel is a homogeneous mixture. This means that its components—primarily iron (Fe) and carbon (C)—are uniformly distributed at a microscopic level. Unlike a heterogeneous mixture, where components are visibly distinct (like sand and water), steel presents a consistent structure throughout. The carbon content is the key differentiator, dictating the properties of different steel grades. However, it's crucial to note that while homogeneous, steel's microscopic structure can be manipulated to exhibit various properties.

The Role of Carbon: A Key Determinant of Steel Properties

The percentage of carbon in steel significantly impacts its characteristics. Low-carbon steel (typically less than 0.3% carbon) is relatively soft, ductile, and easily weldable. This makes it ideal for applications requiring formability, like car bodies and sheet metal. Conversely, high-carbon steel (more than 0.6% carbon) is harder, stronger, and less ductile, offering superior wear resistance. This makes it suitable for tools, cutting instruments, and other high-strength applications.

Beyond Iron and Carbon: Alloying Elements Enhance Properties

While iron and carbon form the foundation of steel, the addition of other alloying elements elevates its properties to an extraordinary degree. These elements, such as manganese (Mn), silicon (Si), chromium (Cr), nickel (Ni), molybdenum (Mo), vanadium (V), tungsten (W), and others, are introduced in controlled amounts to tailor specific characteristics. This precise manipulation allows steelmakers to engineer steel for a vast array of applications, leading to the wide spectrum of steel grades available.

Understanding the Microstructure: A Deeper Dive into Homogeneity

The term "homogeneous" in the context of steel refers to the uniform distribution of elements at the atomic and microscopic level. However, the microstructure, the arrangement of grains and phases within the steel, is far from simple. The microstructure is heavily influenced by the cooling rate after steel is processed. Different cooling rates lead to distinct microstructures, each possessing unique properties.

Phases in Steel: Ferrite, Austenite, and Pearlite

Steel's microstructure is primarily composed of different iron-carbon phases. These phases represent different crystal structures within the material and determine its mechanical properties:

- Ferrite: A body-centered cubic (BCC) structure, ferrite is relatively soft and ductile. It's the dominant phase in low-carbon steels.

- Austenite: A face-centered cubic (FCC) structure, austenite is stable at high temperatures. It's softer and more ductile than ferrite but is not usually found in room-temperature steel. Its presence during heat treatments is critical for controlling the final microstructure.

- Pearlite: A layered structure of ferrite and cementite (Fe3C), pearlite is harder and stronger than ferrite. It forms during the cooling of steel containing moderate amounts of carbon. The arrangement of these layers, known as lamellar spacing, greatly influences strength and ductility.

Heat Treatment: Manipulating the Microstructure for Desired Properties

Heat treatment is a crucial process that manipulates the microstructure of steel. This involves heating the steel to a specific temperature range, holding it at that temperature for a certain time, and then cooling it at a controlled rate. This process can refine the grain size, alter the phases present, and significantly impact the steel's hardness, strength, and ductility. Different heat treatments, such as annealing, normalizing, quenching, and tempering, produce various microstructures tailored to particular applications.

Classifying Steel: A Diverse Family of Materials

The sheer variety of steel grades available highlights the complexity of this material. Steel is categorized based on various criteria, including carbon content, alloying elements, and manufacturing processes. Here are some common classifications:

Carbon Steels: The Foundation of Steel Production

Carbon steels are the simplest form of steel, primarily composed of iron and carbon, with minimal amounts of other elements. They are further categorized based on their carbon content:

- Low-Carbon Steel: (<0.3% carbon) – Soft, ductile, readily weldable. Used in automotive parts, sheet metal, and wire.

- Medium-Carbon Steel: (0.3-0.6% carbon) – Stronger and harder than low-carbon steel. Used in shafts, gears, and railway components.

- High-Carbon Steel: (>0.6% carbon) – Hardest and strongest of the carbon steels. Used in tools, springs, and cutting edges.

Alloy Steels: Enhancing Performance through Alloying Elements

Alloy steels contain significant amounts of alloying elements in addition to iron and carbon. These elements enhance specific properties such as strength, corrosion resistance, and toughness. Some common alloy steels include:

- Stainless Steels: Characterized by their high chromium content (typically over 10.5%), which provides excellent corrosion resistance. Widely used in kitchenware, medical equipment, and architectural applications.

- Tool Steels: High-carbon steels with added alloying elements like tungsten, molybdenum, and vanadium. Possess exceptional hardness, wear resistance, and strength, making them ideal for tools and dies.

- High-Strength Low-Alloy (HSLA) Steels: Optimized for high strength with minimal alloying elements, leading to good weldability and formability. Used extensively in automotive and construction industries.

Applications of Steel: A Material for Every Need

The versatility of steel is reflected in its widespread applications across diverse industries:

- Construction: Steel's strength and durability make it a cornerstone of modern construction, used in buildings, bridges, and infrastructure projects.

- Automotive: Steel forms the backbone of automobiles, with various grades used in different components for optimizing strength, weight, and safety.

- Manufacturing: Steel is essential for machinery, tools, and industrial equipment, where its strength and wear resistance are crucial.

- Energy: Used extensively in pipelines, power generation equipment, and wind turbines.

- Medical: Stainless steel's biocompatibility and corrosion resistance make it ideal for surgical instruments, implants, and medical equipment.

Conclusion: Steel – A Complex and Versatile Material

In conclusion, steel's classification as a homogeneous mixture accurately describes the uniform distribution of its constituents at a microscopic level. However, the complexity of steel goes far beyond this simple description. The precise control over carbon content and the addition of various alloying elements, coupled with heat treatment techniques, allow for the tailoring of its properties to meet a wide spectrum of applications. From the skyscrapers piercing the sky to the intricate components of medical devices, steel's remarkable versatility continues to shape our world. Its enduring strength and malleability will undoubtedly continue to drive innovation and progress for generations to come. Understanding the metallurgy behind steel provides a deeper appreciation of its importance and the engineering marvels it enables.

Latest Posts

Latest Posts

-

Which Is Not A Function Of The Cerebrospinal Fluid

Mar 31, 2025

-

A Vector Has Magnitude And Direction

Mar 31, 2025

-

Oxidation Number Of S In So2

Mar 31, 2025

-

Reduction Of An Aldehyde Produces A

Mar 31, 2025

-

Which Of The Following Is An Example Of A Mixture

Mar 31, 2025

Related Post

Thank you for visiting our website which covers about What Type Of Mixture Is Steel . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.