What Is The Density Of Cork In G/cm3

News Leon

Mar 29, 2025 · 7 min read

Table of Contents

What is the Density of Cork in g/cm³? A Deep Dive into the Properties of this Remarkable Material

Cork, a natural material harvested from the bark of the cork oak tree (Quercus suber), possesses a unique combination of properties that have made it invaluable across a wide range of applications, from wine bottle stoppers to insulation materials. One of the key characteristics defining cork's versatility is its density. But what exactly is the density of cork, and what factors influence this crucial property? This comprehensive article delves into the intricacies of cork density, exploring its measurement, variations, and the implications for its diverse uses.

Understanding Density: A Fundamental Concept

Before diving into the specific density of cork, let's briefly review the concept of density itself. Density is a measure of how much mass is contained within a given volume. It's calculated by dividing the mass of an object by its volume:

Density = Mass / Volume

The standard unit for density is grams per cubic centimeter (g/cm³), although other units like kilograms per cubic meter (kg/m³) are also commonly used. Density is an intrinsic property of a material, meaning it remains constant regardless of the size or shape of the sample. However, it can be influenced by factors such as temperature, pressure, and the material's internal structure.

The Density of Cork: A Range, Not a Single Value

Unlike many synthetic materials with precisely defined densities, cork's density exhibits a degree of variability. This variability stems from several factors, including:

-

Cork Oak Species and Age: Different species of cork oak and the age of the tree influence the density of the harvested bark. Older trees generally yield cork with a slightly higher density.

-

Harvesting and Processing Techniques: The methods used to harvest and process the cork significantly impact its final density. Techniques influencing density include the stripping method, cleaning processes, and any additional treatments applied.

-

Presence of Air Pockets: Cork's cellular structure is characterized by a network of interconnected air cells, which contribute to its low density and excellent insulation properties. The size and distribution of these air pockets influence the overall density. A higher number of larger air pockets leads to lower density.

-

Compression and Aging: Over time, and especially under compression, cork can undergo structural changes, affecting its density. Aged cork might show a slightly higher density than freshly harvested cork due to compression from storage or usage.

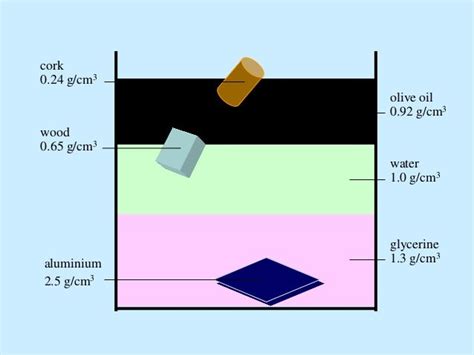

Therefore, instead of a single definitive value, the density of cork is typically given as a range. While sources might vary slightly, a generally accepted range for the density of cork is 0.15 g/cm³ to 0.25 g/cm³. The density often falls within the lower end of this range for uncompressed natural cork, whereas processed and compressed cork might show density values towards the higher end of the range.

Factors Affecting Cork Density and Their Implications

Let's examine in more detail how the factors mentioned above impact the density of cork and the resulting implications for its diverse applications:

1. Cork Oak Species and Age:

The species of cork oak and the age of the tree from which the cork is harvested play a significant role in determining its density. Older trees typically produce cork with a denser structure due to the increased accumulation of suberin, a waxy substance that makes up the cell walls of cork cells. This higher density can be advantageous in applications requiring greater strength and durability.

2. Harvesting and Processing Techniques:

The methods employed during harvesting and processing significantly influence the density of the final product. Careful harvesting minimizes damage to the cork cells, maintaining the integrity of the air pockets and thus influencing the final density. Processing techniques like boiling or steaming can alter the structure and potentially increase the density, while excessive compression during manufacturing can lead to a higher density but may also compromise some of its other advantageous properties.

3. The Role of Air Pockets:

The extensive network of air cells within cork's structure is the primary reason for its low density and excellent insulating properties. These air pockets act as tiny insulators, trapping air and preventing heat transfer. The size and distribution of these air pockets directly correlate with the overall density; a higher number of larger air pockets results in a lower density. The presence of these air pockets also contributes to cork's buoyancy.

4. Compression and Aging:

Cork's compressibility is another important factor. When subjected to compression, the air pockets within the cork are reduced, leading to an increase in density. This characteristic is exploited in various applications, such as wine bottle stoppers, where the compressibility allows for a tight seal. Aging can also cause a slight increase in density due to prolonged compression from storage or use. However, prolonged compression can also affect other properties such as elasticity and resilience.

Applications of Cork Based on Density Considerations

The density of cork directly influences its suitability for different applications. Let's explore some examples:

-

Wine Bottle Stoppers: The low-to-medium density of cork makes it ideal for wine bottle stoppers. Its compressibility ensures a tight seal, preventing air from entering and preserving the wine's quality. Different density cork grades are selected based on the intended wine type and storage period.

-

Insulation Materials: Cork's low density and high porosity make it an excellent thermal and acoustic insulator. It's used in building construction, flooring, and other applications where insulation is critical. The lower the density, the better the insulating properties.

-

Flooring: Cork flooring combines the benefits of its low density with cushioning and resilience. It is a comfortable, warm, and relatively quiet flooring option, frequently chosen for its environmentally friendly qualities. The density of the cork influences the durability and longevity of the flooring.

-

Packaging and Gaskets: Cork's ability to conform to different shapes and its low density make it suitable for use in packaging and gaskets. It can provide effective sealing and cushioning without adding significant weight.

-

Other Applications: The unique properties of cork, coupled with its varying density, enable its use in a wide array of other applications, including bulletin boards, model making, and even in specialized industrial components.

Measuring Cork Density: Practical Methods

Determining the density of a cork sample requires measuring both its mass and volume. While precise laboratory methods exist, several simpler methods can be employed:

1. Water Displacement Method: This is a relatively straightforward method for determining the volume of irregularly shaped objects. The cork sample is carefully submerged in a container of water, and the volume of water displaced is measured. This displaced volume is equal to the volume of the cork. The mass of the cork is determined using a balance scale, and the density is calculated using the formula mentioned earlier.

2. Using a Vernier Caliper and a Balance Scale: For regularly shaped cork samples, a vernier caliper can be used to measure the dimensions (length, width, and height) to calculate the volume. The mass is determined using a balance scale, and the density can then be calculated.

3. Archimedes' Principle: Archimedes' principle, which states that the buoyant force on an object submerged in a fluid is equal to the weight of the fluid displaced, can be used to determine the density of the cork. By measuring the apparent weight loss of the cork when submerged in water, the volume can be calculated.

Conclusion: The Versatile Nature of Cork and its Density

The density of cork, ranging from approximately 0.15 g/cm³ to 0.25 g/cm³, is a critical factor determining its diverse applications. While the specific density value varies depending on numerous factors, understanding this range and the influence of those factors allows for informed material selection and optimal application in diverse industries. Cork's low density coupled with its other unique characteristics – namely, its elasticity, compressibility, and excellent insulation properties – ensures its continued relevance as a sustainable and versatile natural material. Further research into optimizing cork harvesting and processing techniques may lead to even greater control over density and the expansion of cork's already impressive range of uses.

Latest Posts

Latest Posts

-

Which Enzyme Is Not Involved In Dna Replication

Apr 01, 2025

-

A Person Makes A Quantity Of Iced Tea By Mixing

Apr 01, 2025

-

State The Law Of Conservation Of Energy Class 9

Apr 01, 2025

-

Number Of Protons Neutrons And Electrons In Beryllium

Apr 01, 2025

-

What Is The Bond Order Of Li2

Apr 01, 2025

Related Post

Thank you for visiting our website which covers about What Is The Density Of Cork In G/cm3 . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.