Formula Of Coefficient Of Kinetic Friction

News Leon

Mar 19, 2025 · 7 min read

Table of Contents

The Formula of Coefficient of Kinetic Friction: A Deep Dive

The coefficient of kinetic friction, often denoted as μk (mu k), is a crucial concept in physics and engineering, describing the resistance encountered when two surfaces slide against each other. Understanding its formula and the factors influencing it is vital for analyzing various real-world scenarios, from designing brakes to predicting the motion of objects. This article will delve into the formula for the coefficient of kinetic friction, exploring its derivation, practical applications, and limitations.

Understanding Friction: Static vs. Kinetic

Before diving into the formula, it's crucial to differentiate between static and kinetic friction. Static friction is the force that prevents two surfaces from moving relative to each other when a force is applied. Think of trying to push a heavy box across a floor – initially, static friction holds it in place. Once you overcome this static friction and the box starts moving, kinetic friction takes over. Kinetic friction is the force resisting the motion of one surface sliding over another.

The Formula: A Simple yet Powerful Equation

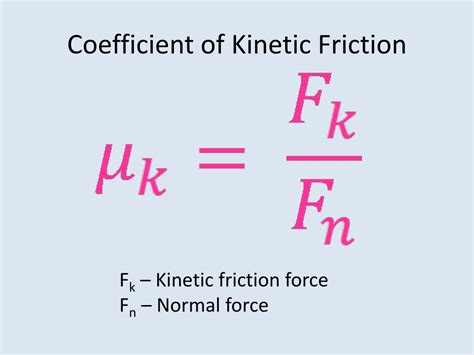

The fundamental formula relating kinetic friction (Fk), the coefficient of kinetic friction (μk), and the normal force (N) is:

Fk = μk * N

Let's break down each component:

1. Kinetic Friction (Fk): The Resisting Force

Kinetic friction (Fk) is the force that opposes the relative motion between two surfaces in contact. It's always directed opposite to the direction of motion. The magnitude of this force depends on the nature of the surfaces and the normal force pressing them together. It's measured in Newtons (N).

2. Coefficient of Kinetic Friction (μk): A Material Property

The coefficient of kinetic friction (μk) is a dimensionless quantity representing the ratio of the frictional force to the normal force. It's a property of the two surfaces in contact, reflecting their roughness and the microscopic interactions between them. A higher μk indicates a greater resistance to sliding. Note that μk is always less than the coefficient of static friction (μs). This means it’s easier to keep an object moving than to start it moving from rest. The value of μk is determined experimentally.

3. Normal Force (N): The Perpendicular Force

The normal force (N) is the force exerted by a surface perpendicular to the surface of contact. It's crucial to remember that the normal force is not always equal to the weight of the object. Consider an object on an inclined plane; the normal force will be less than the weight. It's measured in Newtons (N).

Deriving the Formula: Experimental Basis

The formula Fk = μk * N is not derived from fundamental physical principles like Newton's laws; it's an empirical relationship based on experimental observations. Experiments consistently show that the kinetic frictional force is directly proportional to the normal force. This proportionality constant is defined as the coefficient of kinetic friction (μk).

Experimental Determination of μk

To experimentally determine μk, one would typically perform the following:

- Set up: Place an object on a surface inclined at a small angle.

- Measure: Carefully measure the angle (θ) at which the object begins to slide down the incline at a constant speed.

- Calculate: Use trigonometry to determine the normal force (N) and the component of the weight parallel to the surface (which equals the kinetic friction force Fk when the object slides at constant speed). The normal force is given by N = mgcos(θ), and the kinetic friction force is given by Fk = mgsin(θ).

- Determine μk: Since Fk = μk * N, we can rearrange to solve for μk: μk = Fk / N = mgsin(θ) / mgcos(θ) = tan(θ). Thus, the coefficient of kinetic friction is simply the tangent of the angle of the incline at which the object slides with constant speed.

Factors Affecting the Coefficient of Kinetic Friction

Several factors influence the value of μk:

1. Surface Roughness: Microscopic Interactions

The roughness of the two surfaces plays a dominant role. Rougher surfaces exhibit higher μk values due to increased interlocking and intermolecular forces between the irregularities. Smooth surfaces tend to have lower μk values.

2. Material Properties: Surface Chemistry

The materials themselves significantly impact μk. Different materials possess different surface characteristics, including adhesion, surface energy, and chemical composition, all of which affect frictional interaction. For example, rubber on asphalt has a much higher μk than steel on ice.

3. Lubrication: Reducing Friction

The presence of a lubricant, such as oil or grease, significantly reduces friction by creating a thin film between the surfaces. This film reduces the direct contact between the surfaces, thereby decreasing the intermolecular forces and lowering μk.

4. Temperature: Thermal Effects

Temperature can influence μk, although the effect is often less significant than surface properties. Changes in temperature can affect the material's surface characteristics and consequently the frictional force. Generally, increased temperature can slightly decrease μk for some materials.

5. Speed: Velocity Dependence

While the formula suggests μk is independent of speed, this is only an approximation. At very low speeds, μk can slightly increase. However, for typical speeds, the effect is negligible. At extremely high speeds, other factors, such as air resistance and surface deformation, become more significant.

Applications of the Coefficient of Kinetic Friction

The concept of kinetic friction and its coefficient is crucial in numerous applications across various fields:

1. Automotive Engineering: Braking Systems

Understanding kinetic friction is vital for designing effective braking systems. The frictional force between brake pads and the rotor/drum is responsible for slowing down or stopping a vehicle. Materials with high μk are chosen for brake pads to ensure optimal braking performance.

2. Mechanical Engineering: Machine Design

In machine design, engineers must account for kinetic friction to predict the efficiency of mechanical systems. This helps in selecting appropriate lubricants, optimizing designs to minimize energy losses due to friction, and preventing wear and tear on moving parts.

3. Civil Engineering: Structural Analysis

Kinetic friction is important in structural analysis, particularly when analyzing the stability of structures subject to sliding or movement, such as retaining walls or slopes.

4. Sports Science: Athletic Performance

The coefficient of kinetic friction plays a role in sports, affecting athlete performance. The friction between an athlete's shoes and the playing surface influences traction, speed, and maneuverability.

5. Manufacturing Processes: Material Removal

In manufacturing processes such as machining and grinding, kinetic friction between the cutting tool and the workpiece plays a critical role in determining the cutting forces, surface finish, and material removal rate.

Limitations of the Formula: Beyond the Simple Model

While Fk = μk * N is a useful approximation, it has limitations:

1. Surface Area: No Dependence (Mostly)

The formula suggests no dependence on the surface area. This is largely true for macroscopic surfaces but can break down at the nanoscale or with very small contact areas.

2. Speed Dependence: A Simplification

As mentioned earlier, the formula assumes μk is independent of speed, which is only a reasonable approximation over a limited range of speeds.

3. Material Heterogeneity: Complex Surfaces

The formula assumes uniform material properties. Real-world surfaces are often heterogeneous, with varying roughness and material composition. This can lead to variations in μk across the contact area.

4. Temperature and Pressure Effects: Not Always Negligible

While often neglected, temperature and pressure can significantly influence μk, particularly in extreme conditions.

Conclusion: A Fundamental Tool for Understanding Motion

The formula Fk = μk * N is a fundamental tool for understanding and predicting motion in the presence of kinetic friction. While it's a simplification of a complex phenomenon, it provides a valuable approximation for a wide range of applications. Understanding the factors affecting μk and the limitations of the formula are crucial for accurate analysis and successful engineering design. Further exploration into more advanced models of friction is necessary for scenarios involving complex surface interactions, high speeds, or extreme conditions.

Latest Posts

Latest Posts

-

Is Supporting Combustion A Physical Or Chemical Property

Mar 19, 2025

-

What Class Lever Is A Wheelbarrow

Mar 19, 2025

-

The Sum Of Two Polynomials Is 10a2

Mar 19, 2025

-

Which Of The Following Events Occur During Anaphase I

Mar 19, 2025

-

How Did Hoover React To The Bonus Army

Mar 19, 2025

Related Post

Thank you for visiting our website which covers about Formula Of Coefficient Of Kinetic Friction . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.