What Class Lever Is A Wheelbarrow

News Leon

Mar 19, 2025 · 6 min read

Table of Contents

What Class Lever is a Wheelbarrow? A Comprehensive Guide

The humble wheelbarrow, a tool found on construction sites, farms, and in gardens worldwide, is more than just a simple carrying device. It's a fascinating example of a class 1 lever in action, showcasing the principles of mechanical advantage in a practical and readily understandable way. This article will delve deep into the mechanics of a wheelbarrow, explaining why it's classified as a class 1 lever, exploring its mechanical advantage, and examining the factors that influence its efficiency. We'll also touch upon different lever types and how they compare to the wheelbarrow's design.

Understanding Levers: A Quick Recap

Before we delve into the specifics of the wheelbarrow, let's establish a foundational understanding of levers. A lever is a simple machine consisting of a rigid bar that pivots around a fixed point called a fulcrum. Force is applied to one end of the bar (the effort), and this force is used to move a load at the other end (the resistance). The efficiency of a lever is determined by its mechanical advantage, which is the ratio of the output force (resistance) to the input force (effort).

There are three classes of levers, each distinguished by the relative positions of the fulcrum, effort, and resistance:

Class 1 Levers: Fulcrum in the Middle

In a class 1 lever, the fulcrum is located between the effort and the resistance. This arrangement allows for a mechanical advantage greater than, less than, or equal to 1, depending on the distances between the fulcrum and the effort and resistance points. Examples include seesaws, crowbars, and, as we will explore in detail, wheelbarrows.

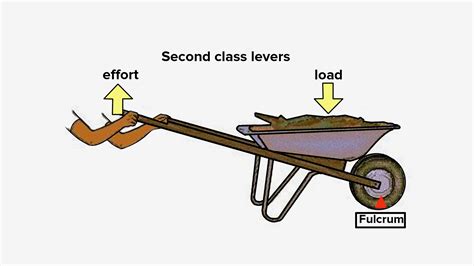

Class 2 Levers: Resistance in the Middle

Class 2 levers have the resistance located between the fulcrum and the effort. These levers always provide a mechanical advantage greater than 1, meaning they amplify the effort applied. Examples include wheelbarrows (depending on how it's used!), bottle openers, and nutcrackers.

Class 3 Levers: Effort in the Middle

In class 3 levers, the effort is located between the fulcrum and the resistance. These levers always have a mechanical advantage less than 1. While they don't amplify force, they amplify distance and speed. Tweezers, fishing rods, and human limbs are all examples of class 3 levers.

Why a Wheelbarrow is a Class 1 Lever

The wheelbarrow's classification as a class 1 lever might seem counterintuitive at first glance, particularly if you consider how the load is positioned. However, careful examination reveals the true nature of its lever system:

- The Fulcrum: The wheel acts as the fulcrum – the pivot point around which the handle moves.

- The Effort: The force applied to the handles by the user constitutes the effort.

- The Resistance: The weight of the material in the tray is the resistance.

The fulcrum (wheel) is situated between the effort (handles) and the resistance (load). This arrangement perfectly aligns with the definition of a class 1 lever.

Important Note: While some might argue that a wheelbarrow can act as a class 2 lever if the load is significantly closer to the wheel than the handles. However, the most efficient use and typical configuration place the wheelbarrow firmly in the class 1 category.

Mechanical Advantage in a Wheelbarrow

The mechanical advantage of a wheelbarrow is directly influenced by the distances between the fulcrum (wheel), the effort (handles), and the resistance (load). A greater distance between the effort and the fulcrum, relative to the distance between the resistance and the fulcrum, results in a higher mechanical advantage. This means less effort is required to lift and move a heavy load.

Mathematically, the mechanical advantage (MA) of a lever is calculated as:

MA = Effort Arm Length / Resistance Arm Length

Where:

- Effort Arm Length: The distance between the fulcrum (wheel) and the point where the effort is applied (handles).

- Resistance Arm Length: The distance between the fulcrum (wheel) and the center of gravity of the load in the tray.

To maximize the mechanical advantage of a wheelbarrow, users should:

- Position the load as close to the wheel as possible: This minimizes the resistance arm length.

- Apply the effort to the handles as far from the wheel as possible: This maximizes the effort arm length.

A wheelbarrow with long handles and a shorter tray will, therefore, possess a greater mechanical advantage than one with short handles and a long tray.

Factors Affecting Wheelbarrow Efficiency

While the lever system is crucial, other factors influence the overall efficiency of a wheelbarrow:

- Wheel Diameter: Larger wheels reduce rolling resistance, making it easier to move the load over uneven terrain.

- Wheel Bearings: Well-lubricated bearings minimize friction, further improving efficiency.

- Tray Design: A well-designed tray will prevent material from spilling and distribute the weight evenly.

- Handle Ergonomics: Handles designed for comfortable gripping and leverage enhance user efficiency and reduce strain.

- Surface Friction: The type of surface the wheelbarrow is used on (e.g., smooth concrete vs. rough dirt) significantly impacts rolling resistance.

Comparing Wheelbarrows to Other Lever Systems

It's instructive to compare the wheelbarrow's functionality to other lever systems:

-

Seesaw: A classic example of a class 1 lever, the seesaw provides a direct comparison. The fulcrum (pivot point) is in the middle, with effort on one side and resistance on the other. The balancing of forces is analogous to the balance in a wheelbarrow as it moves.

-

Crowbar: Also a class 1 lever, a crowbar uses a similar principle to lift heavy objects. The fulcrum is the point where the crowbar rests against an object, the effort is applied to the handle, and the resistance is the object being lifted. This illustrates the power of leverage.

-

Bottle Opener: Often classified as a class 2 lever, the bottle opener highlights how the resistance (bottle cap) is in the middle, allowing a relatively small force to overcome significant resistance. This is a different mechanical advantage configuration compared to the wheelbarrow.

-

Tweezers: As a class 3 lever, tweezers showcase a system where speed and precision are favored over force amplification. This contrasts with the wheelbarrow's focus on moving substantial weight.

Conclusion: The Wheelbarrow as a Masterclass in Simple Machines

The wheelbarrow, often overlooked as a simple tool, is a marvel of engineering. Its classification as a class 1 lever, coupled with its design features, allows it to efficiently move heavy loads with relatively little effort. By understanding the principles of levers, mechanical advantage, and the factors influencing efficiency, we can appreciate the ingenuity and practicality of this ubiquitous device. Its design stands as a testament to the power of simple machines and their continuing impact on various aspects of our daily lives. From construction to gardening, the wheelbarrow serves as a powerful and enduring symbol of human innovation and its ability to harness the fundamental principles of physics for practical purposes. The next time you use a wheelbarrow, take a moment to appreciate the sophisticated interplay of levers, wheels, and human effort that makes it such an indispensable tool.

Latest Posts

Latest Posts

-

What Is The River Behind The Taj Mahal

Mar 19, 2025

-

Why Is The Heart Called A Double Pump

Mar 19, 2025

-

What Percentage Of 8 Is 64

Mar 19, 2025

-

How Many Pints In One Pound

Mar 19, 2025

-

Draw A Six Carbon Alkyne That Can Exist As Diastereomers

Mar 19, 2025

Related Post

Thank you for visiting our website which covers about What Class Lever Is A Wheelbarrow . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.