A Coil Is Formed By Winding 250 Turns

News Leon

Mar 28, 2025 · 7 min read

Table of Contents

A Coil Formed by Winding 250 Turns: Exploring Inductance, Applications, and Design Considerations

A coil, also known as an inductor, is a passive electronic component formed by winding a conductive wire around a core material. When a current flows through the coil, it generates a magnetic field. This ability to store energy in a magnetic field is the defining characteristic of an inductor, and the magnitude of this energy storage is directly related to the number of turns in the coil. This article delves into the properties and applications of a coil formed by winding 250 turns, exploring the factors influencing its inductance, and examining its use in various electrical circuits and systems.

Understanding Inductance and its Relationship to the Number of Turns

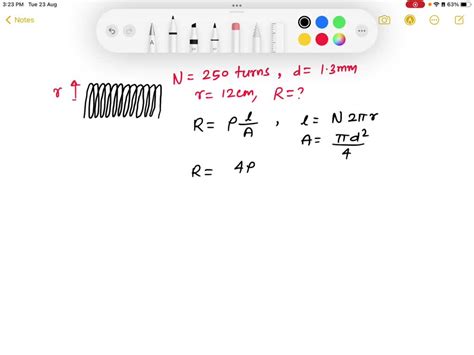

Inductance (L), measured in Henries (H), quantifies a coil's ability to oppose changes in current. A higher inductance means a greater opposition to current fluctuations. The inductance of a coil is significantly influenced by several factors, with the number of turns being a primary contributor. The formula for the inductance of a solenoid (a type of coil with a cylindrical shape) is approximately:

L ≈ (μ₀ * N² * A) / l

Where:

- L is the inductance in Henries (H)

- μ₀ is the permeability of free space (4π × 10⁻⁷ H/m)

- N is the number of turns

- A is the cross-sectional area of the coil in square meters (m²)

- l is the length of the coil in meters (m)

This equation clearly demonstrates the quadratic relationship between the number of turns (N) and the inductance (L). Doubling the number of turns quadruples the inductance, highlighting the significant impact of the number of turns on the coil's properties. A coil with 250 turns will exhibit a considerably higher inductance than one with fewer turns, assuming other parameters remain constant.

The Role of Core Material

The core material around which the coil is wound also plays a crucial role in determining the inductance. Different materials have different permeabilities (μ), which affect the magnetic flux density. Using a ferromagnetic core material, such as iron or ferrite, significantly increases the permeability compared to air or a non-magnetic core. This results in a much higher inductance for the same number of turns and physical dimensions. A coil with 250 turns wound on a ferrite core will have a drastically different inductance compared to a similar coil wound on an air core.

Other Factors Affecting Inductance

Beyond the number of turns and core material, other geometrical factors influence the coil's inductance:

- Coil Diameter: A larger diameter generally leads to higher inductance.

- Coil Length: A longer coil typically results in lower inductance.

- Coil Spacing: The spacing between turns affects the inductance, with tighter winding generally increasing inductance.

Precise calculation of inductance often requires more complex formulas, especially for coils with non-ideal geometries. Simulation software and empirical measurements are often employed for accurate inductance determination.

Applications of a 250-Turn Coil

A coil with 250 turns finds application in a wide array of electronic circuits and systems, depending on its core material, physical dimensions, and operating frequency. Some common applications include:

1. Energy Storage in Inductive Circuits

The ability to store energy in a magnetic field makes coils crucial in various power electronics applications. Energy storage can be particularly beneficial for applications requiring surge protection, smoothing of pulsed currents, or providing temporary energy reserves. A 250-turn coil, particularly with a ferromagnetic core, can effectively manage and store energy in circuits.

2. Filtering and Noise Suppression

Inductors are fundamental components in filters used to remove unwanted frequencies from a signal. They offer high impedance to alternating current (AC) while allowing direct current (DC) to pass relatively unhindered. A 250-turn coil can be part of a low-pass, high-pass, band-pass, or band-stop filter, effectively suppressing noise and unwanted signals in a circuit.

3. Resonant Circuits

Coils are essential components in resonant circuits, which are used in radio frequency (RF) applications, such as radio receivers and transmitters. A resonant circuit consisting of a coil (inductor) and a capacitor exhibits a specific resonant frequency determined by the inductance and capacitance values. The 250-turn coil can be utilized to create a resonant circuit with a desired operating frequency.

4. Transformers

Transformers utilize coils to transfer energy between circuits through electromagnetic induction. A transformer consists of at least two coils (primary and secondary) wound on the same core. The voltage and current in the secondary coil are determined by the turn ratio between the primary and secondary coils. A 250-turn coil could be used as either the primary or secondary coil in a transformer, depending on the required voltage transformation ratio.

5. Sensors and Actuators

Coils are employed in various sensor and actuator applications. For example, a coil can be used as part of a magnetic field sensor to detect changes in magnetic flux, or as an actuator in a solenoid valve, utilizing the magnetic field generated by the current flowing through the coil to control mechanical motion. A 250-turn coil with a ferromagnetic core can be particularly effective in such applications due to its higher inductance.

6. Electromagnetic Relays

Electromagnetic relays use coils to actuate a switch mechanism. When current flows through the coil, it generates a magnetic field that attracts a ferromagnetic armature, closing or opening the switch contacts. The number of turns in the coil dictates the magnetic force generated, and a 250-turn coil can provide sufficient magnetic force for various relay applications.

Design Considerations for a 250-Turn Coil

Designing a 250-turn coil requires careful consideration of several factors to achieve the desired inductance and performance characteristics. These considerations include:

1. Core Material Selection

The choice of core material significantly impacts the inductance, saturation characteristics, and overall performance of the coil. Ferrite cores are common choices due to their high permeability and relatively low losses at higher frequencies. Air cores are used when high-frequency operation with low losses is essential, though they result in lower inductance for a given number of turns.

2. Wire Gauge Selection

The wire gauge determines the coil's resistance and current-carrying capacity. A thicker wire gauge offers lower resistance but increases the overall size and weight of the coil. The choice of wire gauge depends on the intended current and frequency of operation.

3. Winding Technique

Proper winding technique is crucial for achieving uniform inductance and minimizing parasitic capacitances. Different winding methods, such as single-layer winding, multilayer winding, or bifilar winding, each have unique characteristics and suitability for different applications.

4. Coil Form and Dimensions

The physical dimensions of the coil, such as the diameter and length, impact the inductance. Designing the coil geometry to meet the desired inductance and physical constraints requires careful calculation and optimization.

5. Insulation and Shielding

Appropriate insulation is essential to prevent short circuits and electrical breakdown. Shielding may be necessary to minimize electromagnetic interference (EMI) and reduce unwanted coupling with other components.

6. Temperature Considerations

Temperature variations can affect the coil's inductance and resistance. The choice of wire insulation and core material should consider the operating temperature range.

Conclusion

A coil formed by winding 250 turns is a versatile and widely used passive electronic component with a wide range of applications. Its inductance, a crucial parameter, is significantly influenced by the number of turns, core material, and other geometrical factors. Understanding these factors and considering appropriate design considerations are crucial for creating a coil that meets the specific requirements of an application. From energy storage and filtering to resonant circuits and transformers, a well-designed 250-turn coil plays a vital role in numerous electronic systems and circuits. Precise calculations, simulations, and careful consideration of the design parameters are essential to ensure optimal performance in the chosen application. Further research into specific applications and material properties will allow for even more precise and efficient coil designs tailored to specific performance requirements.

Latest Posts

Latest Posts

-

Is Calcium Oxide Ionic Or Covalent

Mar 31, 2025

-

What Is Not True Regarding Antibiotics

Mar 31, 2025

-

Balanced Equation For Copper And Nitric Acid

Mar 31, 2025

-

Passwords Passphrases And Pins Are Examples Of Which Security Term

Mar 31, 2025

-

Both Glucose And Fructose Are

Mar 31, 2025

Related Post

Thank you for visiting our website which covers about A Coil Is Formed By Winding 250 Turns . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.