What Type Of Lever Is A Wheelbarrow

News Leon

Mar 30, 2025 · 5 min read

Table of Contents

What Type of Lever is a Wheelbarrow? A Comprehensive Guide

The humble wheelbarrow. A simple machine used for centuries to move materials, from soil and bricks to rocks and even livestock. But have you ever stopped to consider the physics behind its design? More specifically, what type of lever is a wheelbarrow? Understanding this seemingly simple question unlocks a deeper appreciation for the principles of mechanics and engineering behind this everyday tool. This comprehensive guide will delve into the mechanics of a wheelbarrow, exploring its lever system, class, and the advantages of its design. We'll also touch upon its historical context and variations to provide a complete picture of this fascinating device.

Understanding Levers: A Quick Recap

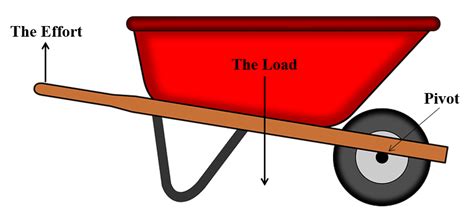

Before we classify the wheelbarrow, let's quickly revisit the basics of levers. A lever is a simple machine consisting of a rigid bar that pivots around a fixed point called a fulcrum. Force is applied to one end of the bar (the effort), causing the other end (the load) to move. The effectiveness of a lever depends on the relative positions of the fulcrum, effort, and load.

Levers are categorized into three classes based on the arrangement of these three components:

- Class 1 Lever: The fulcrum is located between the effort and the load (e.g., seesaw, crowbar).

- Class 2 Lever: The load is located between the fulcrum and the effort (e.g., wheelbarrow, nutcracker).

- Class 3 Lever: The effort is located between the fulcrum and the load (e.g., tweezers, fishing rod).

Wheelbarrow: A Class 2 Lever in Action

Now, let's get to the crux of the matter: a wheelbarrow is a Class 2 lever.

This classification arises from the arrangement of the three key components in its design:

- Fulcrum: The wheel acts as the fulcrum, the pivot point around which the lever rotates.

- Load: The material being transported (soil, bricks, etc.) constitutes the load, positioned between the wheel (fulcrum) and the handles (effort).

- Effort: The force applied to the handles represents the effort, used to lift and move the load.

The strategic positioning of the load between the fulcrum and the effort is the defining characteristic of a Class 2 lever. This arrangement offers a significant mechanical advantage, allowing a relatively small effort to move a much larger load.

Mechanical Advantage: The Power of the Wheelbarrow

The mechanical advantage of a lever is the ratio of the output force (the force exerted on the load) to the input force (the effort applied). In a Class 2 lever like a wheelbarrow, the mechanical advantage is always greater than 1. This means that the wheelbarrow amplifies the effort, enabling the user to lift and move heavier loads than they could manage unaided. The further away the handles are from the wheel (the longer the lever arm), the greater the mechanical advantage.

This is why wheelbarrows are so effective for moving heavy materials; they cleverly utilize the principles of leverage to significantly reduce the effort required. The load is balanced closer to the wheel, reducing the amount of force needed to lift it. Consider trying to lift a heavy load without the wheelbarrow; the difference is immediately apparent.

Variations in Wheelbarrow Design and Lever Principles

While the fundamental principle remains the same – a Class 2 lever – variations in wheelbarrow design can slightly alter the mechanical advantage. Factors influencing this include:

- Wheel Size and Position: Larger wheels, positioned closer to the load, generally offer a greater mechanical advantage. Smaller wheels, positioned farther from the load, may require more effort.

- Handle Length: Longer handles increase the distance from the fulcrum to the effort point, boosting the mechanical advantage and making it easier to lift heavy loads.

- Wheelbarrow Construction: The overall structural integrity and material used in the wheelbarrow can also subtly affect its efficiency as a lever. Stronger, more durable materials can withstand larger loads and enhance performance.

- Load Distribution: Evenly distributing the load within the wheelbarrow is crucial. An unevenly distributed load can compromise stability and reduce the effectiveness of the lever system.

Historical Context: The Evolution of the Wheelbarrow Design

The wheelbarrow's design has evolved over centuries, reflecting advancements in materials science and engineering. Early wheelbarrows were simple, often constructed from wood and employing rudimentary wheel mechanisms. As technology progressed, the incorporation of stronger materials like steel and the development of more efficient wheel designs led to significant improvements in their load-carrying capacity and ease of use.

Understanding the historical context helps appreciate the ingenuity behind the simple yet effective design. The fundamental principles of leverage, however, remain constant, regardless of the specific design iteration.

Beyond the Basics: Exploring Further Applications of Lever Principles

The principles of levers aren't confined to wheelbarrows; they are fundamental to many aspects of engineering and everyday life. From simple tools like pliers and bottle openers to complex machines like cranes and excavators, the concept of leverage plays a crucial role in enhancing efficiency and enabling us to accomplish tasks otherwise impossible with unaided human strength.

Conclusion: The Wheelbarrow's Enduring Legacy

The wheelbarrow stands as a testament to the power of simple mechanics. Its classification as a Class 2 lever underscores its ingenious design, which effectively amplifies effort and makes the movement of heavy loads feasible. By understanding the lever system at play, we gain a deeper appreciation for the engineering principles behind this ubiquitous tool and its enduring legacy in various fields, from construction to agriculture and beyond. The next time you see a wheelbarrow, take a moment to appreciate the physics in action – a simple, yet remarkably effective, application of leverage. The wheelbarrow, a simple class 2 lever, continues to be a vital tool worldwide, demonstrating the power of fundamental physics in our everyday lives. Its evolution reflects advancements in materials and design, but the core principle remains: leverage, making the seemingly impossible, possible.

Latest Posts

Latest Posts

-

A Relationship In Which Two Or More Species Benefit

Apr 01, 2025

-

Which Of The Following Is Not A Physiological Need

Apr 01, 2025

-

Greatest Amount Of Digestion Takes Place In The

Apr 01, 2025

-

All Real Numbers Are Rational Numbers True Or False

Apr 01, 2025

-

Which Of The Following Is A Function That Money Serves

Apr 01, 2025

Related Post

Thank you for visiting our website which covers about What Type Of Lever Is A Wheelbarrow . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.