The Figure Shows Wire 1 In Cross Section

News Leon

Mar 15, 2025 · 6 min read

Table of Contents

Decoding the Cross-Section: A Comprehensive Guide to Understanding Wire 1

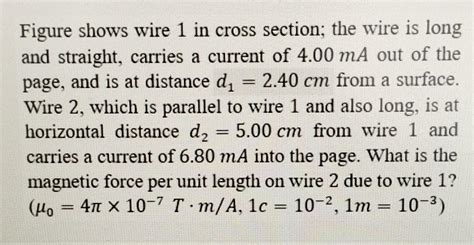

The phrase "the figure shows wire 1 in cross-section" is a common starting point for many engineering, physics, and electrical problems. This seemingly simple statement opens a door to a wealth of information, allowing us to analyze the properties and behavior of the wire. This article delves into the various aspects of understanding a wire's cross-section, exploring the implications of its geometry, material properties, and how this knowledge is crucial in various applications.

What is a Cross-Section?

Before we dive into the specifics of "Wire 1," let's define what a cross-section actually represents. A cross-section is a view of an object as if it were cut through perpendicularly to its longitudinal axis. Imagine slicing a wire cleanly in half; the exposed surface you see is its cross-section. This view is crucial because it reveals the wire's shape, size, and internal structure, all of which influence its electrical and mechanical properties.

Interpreting the Cross-Section of Wire 1: Unveiling the Hidden Information

The simple statement "the figure shows wire 1 in cross-section" assumes the existence of a visual representation—a diagram, image, or drawing—showing the cross-sectional area of the wire. To interpret this information effectively, we must consider several key factors:

1. Shape and Dimensions:

The most immediate piece of information is the shape of Wire 1's cross-section. Is it circular? Rectangular? Oval? Each shape has unique implications. A circular cross-section is the most common for wires due to its efficiency in minimizing resistance and maximizing current-carrying capacity. A rectangular or square cross-section might be found in specialized applications where space constraints dictate the shape. The dimensions of the cross-section—diameter for circular wires, width and height for rectangular wires—are critical for calculating the wire's area.

Importance of Area: The cross-sectional area is fundamental to calculating a wire's:

- Resistance: A larger cross-sectional area reduces resistance. This is because a larger area allows for more electrons to flow, reducing collisions and impeding current flow.

- Current-Carrying Capacity: A larger area means a higher current-carrying capacity. Larger area can dissipate heat more effectively, preventing overheating and damage.

- Strength and Stiffness: The cross-sectional area significantly impacts a wire's mechanical strength and stiffness. A larger area translates to higher strength and resistance to bending or deformation.

2. Material Composition:

The figure showing Wire 1's cross-section may also provide information about the wire's material. This is crucial because the material determines the wire's:

- Conductivity: The material's conductivity dictates how easily it allows electrical current to flow. Copper and aluminum are common choices for their high conductivity.

- Tensile Strength: The material's tensile strength determines its resistance to stretching and breaking under tension.

- Ductility: Ductility refers to the material's ability to be drawn into wires. Materials like copper and aluminum are highly ductile.

- Resistance to Corrosion: Certain materials are more resistant to corrosion than others. Corrosion can significantly degrade a wire's performance.

Identifying the material of Wire 1 is paramount for accurately predicting its electrical and mechanical behavior. The figure might indicate this through labels, legends, or material properties listed in accompanying text.

3. Internal Structure:

While less common in simple wire cross-sections, some illustrations might reveal the internal structure of Wire 1. For example:

- Stranded Wire: The wire might be composed of multiple smaller strands bundled together. Stranded wire is more flexible than solid core wire and is better suited for applications involving movement or vibration.

- Composite Materials: Some specialized wires might use composite materials, combining different materials to enhance specific properties like strength or conductivity.

- Presence of Insulation: The figure might also show the presence and thickness of insulation around Wire 1. This is essential for safety and preventing short circuits. The insulation's material properties would also be relevant.

4. Imperfections and Defects:

Careful examination of the cross-section might reveal any imperfections or defects in Wire 1. These could include:

- Surface roughness: This can influence the wire's resistance.

- Inclusions: Foreign materials embedded within the wire can affect its properties.

- Cracks or voids: These weaken the wire and can lead to failure.

Applications of this Knowledge: Practical Implications of Understanding Wire 1

Understanding the details revealed by the cross-section of Wire 1 has significant practical implications across various engineering disciplines. Here are some examples:

1. Electrical Engineering:

- Circuit Design: Accurate calculation of a wire's resistance is crucial for designing electrical circuits. Incorrect estimations can lead to voltage drops, overheating, and circuit malfunctions. The cross-sectional area directly relates to the resistance.

- Power Transmission: The choice of wire material and cross-sectional area significantly impacts the efficiency of power transmission. Larger cross-sectional areas minimize power losses due to resistance.

- Wiring Safety: Understanding the wire's current-carrying capacity is essential for ensuring electrical safety. Overloading a wire can lead to overheating and potential fire hazards.

2. Mechanical Engineering:

- Strength Calculations: The cross-sectional area is crucial in calculating a wire's tensile strength and its resistance to bending or shear forces. This is vital in designing structures and components where wires are used for support or load-bearing.

- Fatigue Analysis: Understanding the wire's material properties and any internal imperfections is crucial for predicting its fatigue life – how long it can withstand repeated stress before failing.

- Selection of Wire for Specific Applications: The choice of wire for specific applications depends on its mechanical properties, durability, and suitability for the particular environment.

3. Material Science and Manufacturing:

- Quality Control: Analyzing wire cross-sections is a standard quality control procedure in manufacturing to ensure that the wire meets the specified dimensions and material properties.

- Material Characterization: Microscopic examination of the cross-section provides information about the wire's microstructure, revealing details about grain size, phase distribution, and the presence of defects.

- Process Optimization: Analyzing cross-sections helps optimize the wire drawing or manufacturing process to improve the wire's mechanical and electrical properties.

Beyond the Basics: Advanced Considerations

The analysis of Wire 1's cross-section can extend beyond the basic parameters discussed above. Advanced techniques and considerations include:

- Microscopic Analysis: Using microscopes (optical, electron) provides high-resolution images of the cross-section, revealing details about the material's microstructure, including grain size, phase distribution, and the presence of defects.

- Spectroscopic Analysis: Techniques like energy-dispersive X-ray spectroscopy (EDS) can be used to determine the elemental composition of the wire, verifying the material's identity and detecting impurities.

- Finite Element Analysis (FEA): FEA is a powerful computational technique used to simulate the behavior of the wire under different loading conditions, providing insights into its strength, stiffness, and potential failure modes.

Conclusion: The Importance of Visual Interpretation in Engineering

The seemingly simple statement, "the figure shows wire 1 in cross-section," underscores the importance of visual interpretation in various engineering disciplines. A comprehensive understanding of the cross-section's details—shape, dimensions, material, and internal structure—is crucial for accurate analysis, design, and troubleshooting. By considering these factors, engineers can ensure the safe and efficient operation of electrical systems, mechanical structures, and various other applications involving wires. Further exploration using advanced techniques can unlock even deeper insights into the wire's behavior and performance, ultimately leading to improved designs and enhanced reliability. The cross-section is not just a visual representation; it is a window into the wire's properties and capabilities, providing the foundation for informed decision-making.

Latest Posts

Latest Posts

-

Difference Between Associative Property And Commutative Property

Mar 15, 2025

-

3x 4 2x 2 5x 7x 9 58

Mar 15, 2025

-

What Is The Oxidation State Of Mn In Kmno4

Mar 15, 2025

-

Astronauts On The International Space Station Are Weightless Because

Mar 15, 2025

-

Compressibility In Solids Liquids And Gases

Mar 15, 2025

Related Post

Thank you for visiting our website which covers about The Figure Shows Wire 1 In Cross Section . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.