Reaction Of Ethanol With Acetic Acid

News Leon

Mar 24, 2025 · 6 min read

Table of Contents

The Esterification Reaction: A Deep Dive into Ethanol and Acetic Acid

The reaction between ethanol and acetic acid, resulting in the formation of ethyl acetate and water, is a classic example of an esterification reaction. This process, also known as Fischer esterification, is crucial in organic chemistry and finds wide applications in various industries. Understanding the mechanism, kinetics, and factors influencing this reaction is essential for anyone working with organic synthesis or related fields. This comprehensive guide will delve into the intricacies of this reaction, exploring its mechanism, practical applications, and the factors that affect its efficiency.

Understanding Esterification: A Closer Look at the Reaction Mechanism

Esterification, in its simplest form, is the reaction between a carboxylic acid (like acetic acid) and an alcohol (like ethanol) to produce an ester and water. The reaction is reversible, meaning the ester can react with water to regenerate the carboxylic acid and alcohol. This equilibrium nature necessitates understanding the factors influencing the reaction's direction and yield.

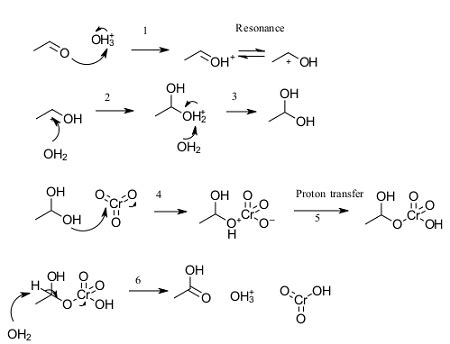

The Acid-Catalyzed Mechanism

The reaction between ethanol and acetic acid is typically catalyzed by a strong acid, commonly concentrated sulfuric acid. This acid plays a crucial role in facilitating the reaction by protonating the carbonyl oxygen of acetic acid. This protonation makes the carbonyl carbon more electrophilic, increasing its susceptibility to nucleophilic attack by the alcohol.

-

Protonation of the carbonyl group: The acid catalyst protonates the carbonyl oxygen of acetic acid, making the carbonyl carbon more electrophilic.

-

Nucleophilic attack: The oxygen atom of the ethanol molecule, possessing a lone pair of electrons, acts as a nucleophile and attacks the electrophilic carbonyl carbon. This forms a tetrahedral intermediate.

-

Proton transfer: A proton is transferred from the hydroxyl group of the tetrahedral intermediate to one of the oxygen atoms, leading to a more stable intermediate.

-

Elimination of water: A molecule of water is eliminated from the intermediate, resulting in the formation of the ester (ethyl acetate).

-

Deprotonation: The protonated ester is deprotonated by a base (often the conjugate base of the acid catalyst), yielding the final ester product, ethyl acetate.

Detailed Step-by-Step Mechanism with Illustrations

While a detailed illustration is beyond the scope of a text-based response, imagine the process as follows:

-

Step 1: The lone pair of electrons on the oxygen of the carbonyl group in acetic acid accepts a proton from the sulfuric acid catalyst, leading to protonation of the carbonyl oxygen. This makes the carbon atom of the carbonyl group more electrophilic.

-

Step 2: The oxygen atom in the hydroxyl group of ethanol, with its lone pair of electrons, attacks the electrophilic carbon atom of the protonated acetic acid. This forms a tetrahedral intermediate with a positive charge on one of the oxygen atoms.

-

Step 3: A proton transfer occurs within the tetrahedral intermediate. A proton shifts from the positively charged oxygen to one of the hydroxyl groups, leading to a more stable intermediate.

-

Step 4: A water molecule is eliminated from the intermediate. This involves a proton transfer and the breaking of a carbon-oxygen bond, leading to the formation of the ester, ethyl acetate.

-

Step 5: The protonated ethyl acetate is then deprotonated by a base (such as the bisulfate ion formed from sulfuric acid), yielding the neutral ethyl acetate molecule.

Factors Affecting the Esterification Reaction

Several factors influence the rate and equilibrium of the esterification reaction. Optimizing these factors is crucial for maximizing the yield of ethyl acetate.

1. Concentration of Reactants

Increasing the concentration of either ethanol or acetic acid will shift the equilibrium towards the formation of ethyl acetate, according to Le Chatelier's principle. A higher concentration of reactants drives the reaction forward, leading to a higher yield of the ester.

2. Acid Catalyst Concentration

The concentration of the acid catalyst (sulfuric acid) also plays a vital role. A higher concentration of the acid catalyst generally increases the reaction rate by increasing the concentration of the protonated intermediate. However, excessively high concentrations can lead to side reactions and potentially reduce the overall yield. Finding the optimal concentration is essential for efficient esterification.

3. Temperature

Temperature significantly influences the reaction rate. Higher temperatures generally accelerate the reaction by increasing the kinetic energy of the molecules, leading to more frequent and energetic collisions. However, extremely high temperatures can lead to side reactions or decomposition of the reactants or products. A moderate temperature increase often proves beneficial.

4. Removal of Water

The esterification reaction is reversible. Removing the water produced during the reaction will shift the equilibrium towards the formation of the ester, according to Le Chatelier's principle. Techniques like azeotropic distillation, where water is removed as part of a low-boiling azeotrope, can be effectively used to improve the yield.

5. Choice of Acid Catalyst

While sulfuric acid is commonly used, other strong acids like hydrochloric acid or p-toluenesulfonic acid can also catalyze the reaction. The choice of acid catalyst can depend on the specific reaction conditions and desired product purity.

Applications of Ethyl Acetate

Ethyl acetate, the product of the reaction between ethanol and acetic acid, has numerous industrial applications due to its unique properties.

1. Solvent

Ethyl acetate is a widely used solvent in various industries. Its low toxicity, relatively high volatility, and ability to dissolve both polar and nonpolar compounds make it suitable for various applications, including:

- Coatings and paints: It's commonly used as a solvent in paints, lacquers, and varnishes.

- Pharmaceuticals: It's used in the production of pharmaceuticals and as a solvent for extraction and purification processes.

- Food industry: It's a food-grade solvent and is used in the extraction of flavors and fragrances.

- Cleaning agents: Its volatile nature makes it suitable for use in cleaning agents and degreasers.

2. Flavor and Fragrance

Ethyl acetate possesses a characteristic fruity odor, reminiscent of pears and bananas. This makes it a valuable component in the food and fragrance industries, where it's used to impart fruity notes to various products.

3. Chemical Intermediate

Ethyl acetate serves as a valuable intermediate in the synthesis of other chemicals. It can be used as a starting material for the production of various other compounds, broadening its applicability in different chemical processes.

Experimental Considerations and Safety Precautions

Conducting the esterification reaction requires careful attention to experimental procedures and safety precautions.

1. Acid Handling

Sulfuric acid is a corrosive and hazardous chemical. Appropriate safety measures, including the use of gloves, eye protection, and a well-ventilated area, are crucial.

2. Heating and Refluxing

Heating the reaction mixture often necessitates refluxing to prevent loss of volatile components. Proper use of reflux condensers is crucial to maintain a safe and controlled reaction.

3. Purification Techniques

The crude ethyl acetate obtained after the reaction requires purification to remove impurities, usually through distillation or extraction. Understanding these techniques is essential for obtaining a pure product.

4. Waste Disposal

Appropriate disposal methods for chemical waste, including unused reactants and by-products, should be strictly followed to minimize environmental impact.

Conclusion

The reaction between ethanol and acetic acid to produce ethyl acetate is a fundamental example of esterification, highlighting the importance of organic chemistry reactions in various industrial processes. Understanding the reaction mechanism, affecting factors, and applications of the product is essential for researchers, chemists, and anyone involved in organic synthesis or related fields. By carefully considering the parameters affecting the reaction yield and safety precautions, one can efficiently produce ethyl acetate and leverage its wide-ranging applications. The reversible nature of the reaction underscores the need for techniques like water removal to maximize the yield of the desired ester. This detailed explanation aims to provide a comprehensive understanding of this significant chemical process.

Latest Posts

Latest Posts

-

What Is The Conjugate Base Of Nh4

Mar 25, 2025

-

How Many Years Did Rip Van Winkle Sleep

Mar 25, 2025

-

Number Of Valence Electrons In Calcium

Mar 25, 2025

-

A Proton A Deuteron And An Alpha Particle Are Accelerated

Mar 25, 2025

-

Hole In A Bone Is Called

Mar 25, 2025

Related Post

Thank you for visiting our website which covers about Reaction Of Ethanol With Acetic Acid . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.