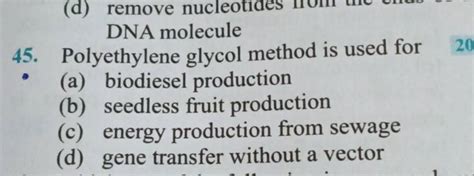

Polyethylene Glycol Method Is Used For

News Leon

Mar 28, 2025 · 6 min read

Table of Contents

Polyethylene Glycol (PEG): Applications and Methods Across Diverse Fields

Polyethylene glycol (PEG), also known as macrogol, is a versatile polymer with a wide range of applications spanning various industries. Its unique properties, including its biocompatibility, water solubility, and ability to be modified chemically, make it an indispensable tool in numerous scientific and industrial processes. This article will delve into the diverse applications of PEG, exploring the underlying methodology behind its use in each context.

What is Polyethylene Glycol (PEG)?

PEG is a synthetic polymer composed of repeating units of ethylene oxide. The molecular weight of PEG can vary significantly, ranging from a few hundred to several million Daltons. This variation in molecular weight directly impacts its properties and therefore its suitability for different applications. Lower molecular weight PEGs tend to be liquid at room temperature, while higher molecular weight PEGs are solid, waxy substances.

The properties of PEG that contribute to its versatility include:

- Biocompatibility: PEG is generally considered biocompatible, meaning it doesn't elicit adverse reactions when in contact with living tissues. This characteristic is crucial for its use in biomedical applications.

- Water Solubility: PEG is readily soluble in water, a feature that makes it suitable for aqueous-based solutions and formulations.

- Chemical Modifiability: PEG's chemical structure allows for easy modification, enabling the attachment of various functional groups to tailor its properties for specific applications.

- Low Toxicity: PEG exhibits relatively low toxicity, enhancing its safety profile for various uses.

Polyethylene Glycol Method: Applications Across Industries

The "polyethylene glycol method" isn't a singular, standardized procedure. Instead, it refers to the various techniques that utilize PEG's properties to achieve specific outcomes. The method employed depends heavily on the desired application. Let's explore some key areas:

1. PEGylation in Biopharmaceuticals

PEGylation is a prominent application of PEG in the pharmaceutical industry. This process involves covalently attaching PEG chains to therapeutic proteins or other biomolecules. The benefits of PEGylation include:

- Increased Plasma Half-life: PEGylation can significantly extend the circulation time of drugs in the bloodstream, reducing the frequency of administration.

- Reduced Immunogenicity: The PEG coating can mask the drug's epitopes, reducing its recognition by the immune system and minimizing adverse immune responses.

- Improved Solubility and Stability: PEGylation can enhance the solubility and stability of therapeutic proteins, particularly those that are prone to aggregation or degradation.

The PEGylation Method: The precise method of PEGylation varies based on the target molecule and the desired properties. Common approaches include:

- Site-specific PEGylation: This technique involves attaching PEG to a specific site on the biomolecule, providing greater control over the properties of the conjugate.

- Random PEGylation: This involves attaching PEG molecules to various sites on the biomolecule, often resulting in a heterogeneous mixture of conjugates.

The choice of PEGylation method significantly impacts the efficacy and safety of the final product.

2. PEG in Cosmetics and Personal Care Products

PEGs are widely used in cosmetics and personal care products due to their moisturizing and emulsifying properties. They act as:

- Humectants: PEGs attract and retain moisture, keeping the skin hydrated.

- Emulsifiers: PEGs help combine oil and water, creating stable emulsions in products like creams and lotions.

- Solvents: PEGs can dissolve various ingredients in cosmetic formulations.

The PEG Method in Cosmetics: The incorporation of PEGs into cosmetic formulations is relatively straightforward. They are typically added during the manufacturing process, where their properties contribute to the desired texture, consistency, and stability of the final product. The specific PEG used is selected based on its molecular weight and other properties to optimize the product's performance.

3. PEG in Drug Delivery Systems

PEG plays a crucial role in advanced drug delivery systems, enhancing drug targeting and controlled release. PEG-based polymers are used to create:

- Liposomes: PEGylated liposomes are used to encapsulate drugs and deliver them to specific target sites within the body. The PEG coating improves the liposome's circulation time and reduces clearance by the reticuloendothelial system (RES).

- Micelles: PEG-modified micelles can encapsulate hydrophobic drugs and enhance their solubility and bioavailability.

- Hydrogels: PEG-based hydrogels are used as matrices for controlled drug release, ensuring sustained delivery of the therapeutic agent.

The PEG Method in Drug Delivery: The preparation of these PEG-based drug delivery systems involves specific techniques such as film hydration, solvent evaporation, or emulsion methods. The choice of method depends on the specific system and the drug being encapsulated. The properties of the resulting system are carefully characterized to ensure controlled release and targeted delivery.

4. PEG as a Cryoprotectant

PEG is used as a cryoprotectant in various applications, protecting cells and tissues from damage during freezing and thawing processes. PEG acts by:

- Reducing ice crystal formation: PEG disrupts the formation of large ice crystals that can damage cell membranes.

- Preventing dehydration: PEG helps maintain cell hydration during freezing.

The PEG Method as Cryoprotectant: The concentration of PEG used as a cryoprotectant depends on the specific cells or tissues being preserved. Optimal PEG concentrations are determined experimentally to maximize cell viability after freezing and thawing. The cryopreservation process often involves a controlled freezing rate to minimize ice crystal formation and subsequent cell damage.

5. PEG in Industrial Applications

Beyond biomedical applications, PEG finds use in various industrial settings:

- Lubricants: PEGs are used as lubricants due to their low viscosity and excellent lubricating properties.

- Anti-static agents: PEGs reduce static electricity buildup in various materials.

- Surfactants: PEGs act as surfactants, reducing surface tension and improving the compatibility of different substances.

- Polymer synthesis: PEGs serve as a building block in the synthesis of various polymers.

- Separation techniques: PEGs are used in liquid-liquid extraction and other separation processes.

The PEG Method in Industrial Applications: The method of using PEG in industrial settings varies greatly depending on the application. It may involve simple mixing, incorporation into formulations, or complex chemical modifications. The specific properties of the PEG used, such as molecular weight, are selected based on the desired outcome.

6. PEG in Research and Development

PEGs are widely utilized in various scientific research applications, including:

- Protein purification: PEG is used as a precipitation agent to separate proteins from other components in a mixture.

- Cell culture: PEG is used as a component in cell culture media.

- Biomaterial engineering: PEG is used to create various biomaterials, such as hydrogels and scaffolds for tissue engineering.

- Drug discovery: PEG is used in high-throughput screening assays for drug discovery.

- Nanotechnology: PEGs are utilized in the design and functionalization of nanoparticles.

The PEG Method in Research: The methodology used in research applications involving PEG depends entirely on the specific application. It may involve techniques such as precipitation, chromatography, encapsulation, or conjugation. Precise control over PEG properties is crucial for obtaining reliable and reproducible results.

Safety Considerations of Polyethylene Glycol

While generally considered safe, some individuals may experience allergic reactions to PEG. These reactions are usually mild, but severe allergic reactions are possible. The potential toxicity of PEG depends on its molecular weight and the route of administration. Lower molecular weight PEGs are more readily absorbed and may have slightly higher toxicity than higher molecular weight PEGs. Always adhere to safe handling procedures and follow relevant safety guidelines when working with PEG.

Conclusion

Polyethylene glycol (PEG) is a remarkable polymer with a remarkable array of applications. Its unique properties, coupled with the diverse methodologies employed in its utilization, makes it an invaluable tool across multiple fields. From biopharmaceuticals to cosmetics, industrial applications to scientific research, PEG's influence is undeniable. While further research continues to expand its applications, the understanding of its diverse methodologies will continue to drive innovation and advancements across various industries. The adaptability of PEG ensures that its importance will only continue to grow in the future.

Latest Posts

Latest Posts

-

Si Unit Of Density Of Water

Mar 31, 2025

-

What Is The Molecular Geometry Of Bef2

Mar 31, 2025

-

Attached Earlobes Is A Recessive Trait In Humans

Mar 31, 2025

-

How Many Electrons Does Nitrogen Have In Its Outer Shell

Mar 31, 2025

-

Which Electrolyte Is A Major Cation In Body Fluid

Mar 31, 2025

Related Post

Thank you for visiting our website which covers about Polyethylene Glycol Method Is Used For . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.