A Lever Rotates Around A Fixed Point Called A

News Leon

Mar 15, 2025 · 7 min read

Table of Contents

A Lever Rotates Around a Fixed Point Called a Fulcrum: Understanding Simple Machines and Their Applications

A lever is one of the simplest yet most effective machines known to humankind. Its fundamental design, involving a rigid bar rotating around a fixed point, has powered countless inventions and continues to play a vital role in modern technology. Understanding the mechanics of a lever, specifically its reliance on a fulcrum, is crucial to appreciating its power and diverse applications. This article delves deep into the world of levers, exploring their physics, types, advantages, disadvantages, and real-world examples.

What is a Fulcrum?

The fulcrum is the cornerstone of any lever system. It's the fixed point around which the lever rotates. Think of it as the pivot point – the location where the lever is supported and allowed to move freely. Without a stable and well-placed fulcrum, the lever would be ineffective. The fulcrum's position relative to the effort (force applied) and the load (resistance being moved) determines the lever's mechanical advantage.

Types of Levers: A Classification Based on Fulcrum Position

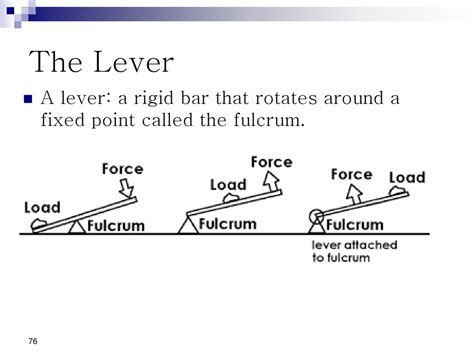

Levers are categorized into three classes based on the relative positions of the fulcrum, effort, and load:

Class 1 Levers: Fulcrum in the Middle

In a Class 1 lever, the fulcrum is located between the effort and the load. This arrangement provides a variety of mechanical advantages depending on the distances between the fulcrum and the effort and load. A seesaw is a classic example; the fulcrum is the central pivot point, the effort is the force applied by one person, and the load is the weight of the other person (and perhaps their portion of the seesaw). Other examples include:

- Scissors: The fulcrum is the rivet connecting the two blades. The effort is applied at the handles, and the load is the material being cut.

- Crowbars: The fulcrum is the point where the crowbar rests against an object. The effort is applied at the opposite end, and the load is the object being moved.

- Pliers: Similar to scissors, the fulcrum is the rivet, the effort is applied at the handles, and the load is the object being gripped.

- Balance Scales: The fulcrum is the central pivot point, the effort is the unknown weight, and the load is the known weight.

Advantages of Class 1 Levers: They can multiply force, change the direction of force, and provide a mechanical advantage depending on the lever's arm lengths.

Disadvantages of Class 1 Levers: A disadvantage might be the need for a substantial distance to move the load, thereby demanding more effort sometimes.

Class 2 Levers: Load in the Middle

In a Class 2 lever, the load is located between the fulcrum and the effort. This arrangement inherently provides a mechanical advantage greater than 1, meaning less effort is required to move a heavier load. Examples include:

- Wheelbarrows: The fulcrum is the wheel, the load is the material in the wheelbarrow, and the effort is applied at the handles.

- Nutcrackers: The fulcrum is the hinge, the load is the nut, and the effort is applied at the handles.

- Bottle Openers: The fulcrum is the point where the opener rests against the bottle cap, the load is the bottle cap, and the effort is applied at the handle.

- Door Hinges: (While seemingly simple, the door acts as a lever. The hinge is the fulcrum, the weight of the door is the load, and the effort is applied to open or close the door.)

Advantages of Class 2 Levers: These levers always offer a mechanical advantage greater than 1, making them efficient for moving heavy loads with less effort.

Disadvantages of Class 2 Levers: The distance the load moves is always less than the distance the effort moves.

Class 3 Levers: Effort in the Middle

In a Class 3 lever, the effort is located between the fulcrum and the load. This configuration prioritizes speed and distance over force multiplication. While these levers don't provide a mechanical advantage greater than 1 (meaning more effort is required than the load), they offer other valuable properties. Examples include:

- Tweezers: The fulcrum is the hinge, the effort is applied at the gripping points, and the load is the object being picked up.

- Fishing Rods: The fulcrum is the rod's base near the hand, the effort is applied near the reel, and the load is the fish.

- Human Forearm: The elbow acts as the fulcrum, the biceps muscle provides the effort, and the load is the weight of the hand and the object it holds.

- Baseball Bat: The hands are the fulcrum (though it's more of a dynamic fulcrum during swing), the effort is applied by the swing, and the load is the ball.

Advantages of Class 3 Levers: These levers excel at increasing speed and distance. The load moves further than the effort, which is beneficial in many applications.

Disadvantages of Class 3 Levers: A mechanical disadvantage is inherent; more effort is required than the magnitude of the load.

Mechanical Advantage: The Power of Levers

The mechanical advantage (MA) of a lever is a measure of how much it multiplies force. It's calculated as the ratio of the output force (load) to the input force (effort). For ideal levers (neglecting friction), the mechanical advantage is also equal to the ratio of the distance from the fulcrum to the effort (effort arm) to the distance from the fulcrum to the load (load arm):

MA = Load/Effort = Effort Arm/Load Arm

A mechanical advantage greater than 1 means the lever multiplies force, making it easier to lift or move heavy objects. A mechanical advantage less than 1 means the lever multiplies distance, making it useful for tasks requiring speed and range of motion.

Real-World Applications: Levers in Action

Levers are ubiquitous in our daily lives and across various industries. Their applications are vast and span a broad range of scales:

- Construction and Engineering: Cranes, excavators, and other heavy machinery utilize lever principles to lift and move massive loads. These systems often incorporate complex combinations of levers and pulleys to maximize efficiency.

- Manufacturing and Industry: From simple tools like wrenches and screwdrivers to sophisticated robotic arms, levers play a critical role in automation and precision work. The efficiency of these machines relies heavily on the proper selection and placement of the fulcrum.

- Medicine and Healthcare: Surgical instruments, orthopedic devices, and even simple tools like forceps all utilize the principles of levers for precise movements and force applications.

- Sports and Recreation: Many sports involve levers, either directly or indirectly. The human body itself acts as a complex system of levers, facilitating movement and power generation. Examples include the motion of a tennis serve, a golf swing, or cycling.

- Household Items: Everyday tools such as can openers, nail clippers, and even the simple act of using a hammer are examples of leverage in action.

Beyond the Basics: Factors Affecting Lever Performance

While the basic principles of levers are straightforward, several factors can influence their performance:

- Friction: Friction at the fulcrum reduces the lever's efficiency, decreasing its mechanical advantage. Proper lubrication can mitigate this effect.

- Material Strength: The lever's material must be strong enough to withstand the forces involved without bending or breaking.

- Fulcrum Stability: A poorly designed or unstable fulcrum can lead to inaccurate movements and reduced efficiency.

- Weight of the Lever: The weight of the lever itself can influence the mechanical advantage, particularly in cases where the lever is relatively heavy compared to the load.

Conclusion: The Enduring Importance of Levers

The lever, a seemingly simple machine revolving around a single point—the fulcrum—holds immense significance in engineering, technology, and even our everyday routines. By understanding the three classes of levers and their respective mechanical advantages, we gain a profound appreciation for this fundamental machine’s enduring impact on our world. From the most basic hand tools to sophisticated industrial machinery, the lever continues to be a testament to the power of simplicity and ingenuity. The next time you use a simple tool, take a moment to recognize the fundamental principle of the lever and its role in making your task easier. It is a reminder of the timeless and powerful influence of physics in our everyday lives.

Latest Posts

Latest Posts

-

Which Of The Following Events Does Not Occur During Prophase

Mar 15, 2025

-

Similarities Between First And Second Great Awakening

Mar 15, 2025

-

How Many Seconds Are In 3 Days

Mar 15, 2025

-

Which Of The Following Has The Least Resistance

Mar 15, 2025

-

Cytokinesis Overlaps With Which Phase Of Mitosis

Mar 15, 2025

Related Post

Thank you for visiting our website which covers about A Lever Rotates Around A Fixed Point Called A . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.