A Copper Wire Of Cross Sectional Area

News Leon

Mar 15, 2025 · 6 min read

Table of Contents

Understanding Copper Wire: A Deep Dive into Cross-Sectional Area and its Implications

Copper wire, a ubiquitous component in electrical systems worldwide, plays a crucial role in conducting electricity. Its performance, however, is intricately linked to its physical properties, most notably its cross-sectional area. This article will explore the significance of copper wire's cross-sectional area, examining its impact on electrical characteristics, practical applications, and the crucial considerations for selection in various scenarios.

What is Cross-Sectional Area?

The cross-sectional area of a copper wire refers to the area of a transverse slice through the wire. Imagine cutting the wire cleanly; the exposed surface represents its cross-sectional area. For a perfectly cylindrical wire, this area is simply calculated using the formula: Area = πr², where 'r' is the radius of the wire. This seemingly simple measurement, however, has profound implications for the wire's electrical and physical properties.

Units of Measurement

Cross-sectional area is typically measured in square millimeters (mm²) or circular mils (cmil). While mm² is the standard unit in the International System of Units (SI), cmil is frequently used in North America, particularly in electrical engineering contexts. It's crucial to understand the conversion between these units to avoid errors in calculations and comparisons. One square millimeter is approximately equal to 1973.5 cmil.

The Impact of Cross-Sectional Area on Electrical Properties

The cross-sectional area of a copper wire directly affects several key electrical characteristics:

1. Electrical Resistance

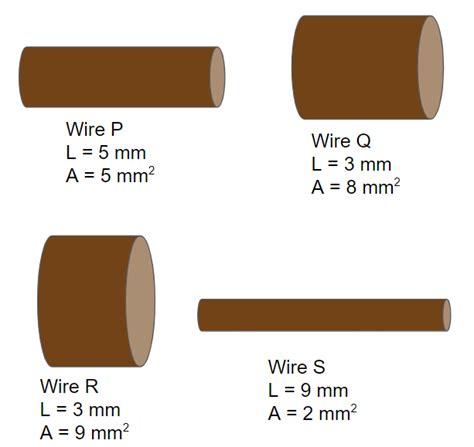

This is perhaps the most significant impact. A larger cross-sectional area signifies a lower resistance. This is because electrons have a larger area to flow through, encountering less resistance from the copper atoms. The relationship is inversely proportional: doubling the cross-sectional area halves the resistance, assuming all other factors remain constant (length, temperature, and material purity). This is described by the formula:

R = ρL/A

where:

- R is the resistance

- ρ (rho) is the resistivity of copper

- L is the length of the wire

- A is the cross-sectional area

2. Current Carrying Capacity (Ampacity)

A larger cross-sectional area allows the wire to carry a higher current without overheating. This is because a greater area reduces the current density (current per unit area). Higher current density generates more heat, which can damage the insulation or even cause a fire. Therefore, ampacity is directly related to cross-sectional area; larger wires can handle more current safely. Ampacity ratings are crucial for selecting appropriate wiring for specific applications and are often specified in electrical codes and standards.

3. Voltage Drop

While not directly determined solely by cross-sectional area, it is strongly influenced by it. A larger cross-sectional area results in a lower voltage drop along the length of the wire. Voltage drop is the decrease in voltage across a wire due to resistance. Minimizing voltage drop is essential to ensure that equipment receives the correct voltage for optimal operation. Longer wires, particularly those carrying large currents, are more prone to significant voltage drop, emphasizing the importance of selecting appropriately sized wires.

Practical Applications and Selection Considerations

The choice of copper wire with the appropriate cross-sectional area depends heavily on the specific application. Several factors influence this decision:

1. Power Transmission

In high-power applications like long-distance power lines, extremely large cross-sectional area wires are necessary to minimize resistance and voltage drop over long distances. The substantial currents involved necessitate conductors with ample capacity to prevent overheating and energy loss. These applications often utilize bundled conductors or specialized high-voltage cables.

2. Household Wiring

Household wiring requires careful consideration of ampacity. Different circuits have different current demands, such as lighting circuits (lower current) versus appliance circuits (higher current). Electrical codes specify minimum wire sizes for various circuits based on their current requirements to ensure safety and prevent overheating.

3. Electronic Devices

In smaller electronic devices, the required current is typically low, allowing for the use of thin wires with smaller cross-sectional areas. Miniaturization demands wires that can fit within compact spaces while still providing adequate conductivity. The emphasis is often on flexibility and space constraints rather than high current carrying capacity.

4. Motor Winding

Motor windings require wire with specific electrical and mechanical properties. The cross-sectional area influences the motor's torque, efficiency, and overall performance. The choice of wire size is a critical factor in motor design and optimization. Factors like winding temperature limits also play a significant role.

5. Automotive Wiring

Automotive wiring systems utilize a range of wire sizes depending on the application. High-current applications, like starting motors, need thick wires, while smaller wires are adequate for lower current applications like lighting or sensors. Factors like vibration resistance and flexibility also contribute to wire selection.

Factors Beyond Cross-Sectional Area

While cross-sectional area is crucial, other factors also affect the performance of copper wire:

1. Material Purity

The purity of the copper significantly influences its conductivity. Higher purity copper possesses lower resistivity, resulting in improved performance. Impurities can increase resistance and reduce current-carrying capacity.

2. Temperature

Copper's resistance increases with temperature. This effect is significant and must be considered, especially in high-current applications where temperature rise can be substantial. The temperature coefficient of resistance for copper is a critical parameter in various calculations and design considerations.

3. Insulation

The insulation surrounding the copper wire plays a vital role in safety and preventing short circuits. The insulation's thermal properties also impact the wire's ability to dissipate heat. The choice of insulation depends on the operating temperature range and the specific environmental conditions.

Advanced Considerations: Skin Effect and Proximity Effect

At higher frequencies, the current tends to flow primarily on the surface of the conductor, a phenomenon known as the skin effect. This reduces the effective cross-sectional area and increases resistance. The depth of current penetration is inversely proportional to the square root of the frequency. At very high frequencies, only a thin layer of the copper wire is effectively used for conduction.

The proximity effect occurs when multiple conductors are close together, causing unequal current distribution across their cross-sections. This effect increases resistance and should be considered in high-frequency applications or when wires are bundled tightly.

Conclusion

The cross-sectional area of copper wire is a fundamental parameter impacting its electrical performance and practical applications. Understanding its relationship to resistance, ampacity, and voltage drop is crucial for selecting appropriate wire sizes in diverse situations. Factors beyond the cross-sectional area, including material purity, temperature, insulation, skin effect, and proximity effect, must also be considered for optimal design and safe operation. Accurate calculations, adherence to electrical codes, and a comprehensive understanding of the wire's properties are essential for successful implementation in any electrical system. Careful selection and appropriate sizing of copper wires are crucial for safety, efficiency, and the reliable performance of electrical installations.

Latest Posts

Latest Posts

-

Concave Mirror And Convex Mirror Difference

Mar 15, 2025

-

Which Is Not A Cranial Bone Of The Skull

Mar 15, 2025

-

Mountain Range That Separates Europe And Asia

Mar 15, 2025

-

16 Out Of 40 As A Percentage

Mar 15, 2025

-

Which Of The Following Is A True Solution

Mar 15, 2025

Related Post

Thank you for visiting our website which covers about A Copper Wire Of Cross Sectional Area . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.