What Is The Density Of Aluminium

News Leon

Mar 25, 2025 · 6 min read

Table of Contents

What is the Density of Aluminum? A Deep Dive into the Properties of This Lightweight Metal

Aluminum, a ubiquitous metal found in everything from soda cans to airplanes, is renowned for its lightweight yet surprisingly strong nature. This characteristic is intrinsically linked to its density, a crucial property influencing its wide range of applications. Understanding the density of aluminum is key to appreciating its versatility and importance in modern society. This article will explore the density of aluminum in detail, examining its measurement, variations, and implications across diverse industries.

Defining Density: Mass per Unit Volume

Before delving into the specifics of aluminum's density, let's establish a fundamental understanding of the concept. Density is a physical property defined as the mass of a substance per unit volume. It's essentially a measure of how tightly packed the atoms are within a material. The formula for density is:

Density (ρ) = Mass (m) / Volume (V)

Density is typically expressed in units of grams per cubic centimeter (g/cm³), kilograms per cubic meter (kg/m³), or pounds per cubic foot (lb/ft³). The choice of unit depends on the context and the scale of the application.

The Density of Aluminum: A Typical Value

The density of pure aluminum at room temperature (approximately 20°C or 68°F) is generally accepted to be around 2.70 g/cm³ or 2700 kg/m³. This value is relatively consistent across various samples of pure aluminum. However, it's crucial to understand that slight variations can occur depending on factors such as:

-

Purity: The presence of alloying elements can alter the density. Aluminum alloys, which are far more common in practical applications than pure aluminum, will have densities that differ slightly from this standard value. The specific density will depend on the composition of the alloy.

-

Temperature: Density is temperature-dependent. As temperature increases, the volume of a material generally expands, leading to a decrease in density. Conversely, a decrease in temperature results in an increase in density. While the change might be relatively small within a reasonable temperature range, it's a factor to consider in precise engineering calculations.

-

Pressure: While the effect is less pronounced than temperature, pressure also affects density. Increased pressure can slightly compress the material, leading to a higher density. This factor is usually less significant in most applications unless dealing with extremely high pressures.

-

Crystal Structure: The arrangement of atoms within the aluminum's crystal structure can subtly influence density. Although aluminum typically adopts a face-centered cubic (FCC) structure, imperfections or variations in this structure can introduce minor density changes.

Aluminum Alloys and Their Densities

The vast majority of aluminum applications utilize aluminum alloys rather than pure aluminum. These alloys incorporate other elements such as copper, magnesium, silicon, zinc, and manganese to enhance specific properties like strength, corrosion resistance, or machinability. The addition of these alloying elements invariably alters the density of the resulting material. The density of an aluminum alloy depends entirely on its specific composition. For instance:

-

Aluminum 6061: A commonly used alloy known for its strength and weldability, typically has a density slightly higher than pure aluminum.

-

Aluminum 2024: A high-strength aircraft alloy, often exhibits a higher density due to the presence of copper and other alloying elements.

-

Aluminum 5052: A marine-grade alloy renowned for its corrosion resistance, may have a density slightly different from pure aluminum.

To determine the exact density of a specific aluminum alloy, one must consult the alloy's datasheet provided by the manufacturer. These datasheets contain precise information on the alloy's composition and properties, including its density at various temperatures.

Significance of Aluminum's Density in Various Applications

The relatively low density of aluminum is a key factor driving its widespread use across numerous industries. This lightweight nature makes it ideal for applications where weight reduction is crucial:

Transportation:

-

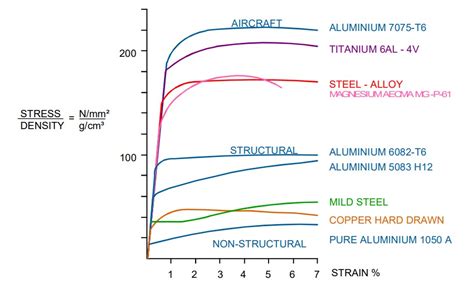

Aerospace: Aluminum alloys are essential in aircraft construction due to their high strength-to-weight ratio. This allows for lighter aircraft, leading to fuel efficiency and improved performance.

-

Automotive: Aluminum's use in car bodies, wheels, and engine components contributes to enhanced fuel economy and improved handling.

-

Rail Transport: Aluminum is employed in the construction of high-speed trains, reducing weight and increasing efficiency.

Packaging:

-

Food and Beverage: Aluminum's malleability and corrosion resistance make it ideal for cans and foil packaging. Its low density keeps transportation costs low.

-

Pharmaceuticals: Aluminum foil is used extensively in pharmaceutical packaging to protect sensitive medications from moisture and light.

Construction:

-

Building Materials: Aluminum is used in window frames, roofing, and cladding due to its durability and lightweight nature.

-

Bridges and Structures: Aluminum's strength and corrosion resistance are exploited in bridge construction and other structural applications.

Electrical Applications:

- Wiring and Cables: Aluminum's excellent electrical conductivity makes it a suitable choice for electrical wiring and cables, particularly in large-scale power transmission applications. Its lower density compared to copper can translate into cost savings.

Other Applications:

Aluminum's versatility extends to countless other applications, including consumer electronics, kitchenware, sporting goods, and more. Its low density often contributes to the portability and ease of use of these products.

Measuring the Density of Aluminum: Experimental Methods

While readily available tables provide typical density values for aluminum and its alloys, there are experimental methods to determine the density of a particular sample. These methods generally involve measuring both the mass and volume of the sample.

-

Archimedes' Principle: This classic method utilizes water displacement to measure the volume of an irregularly shaped object. The object is submerged in water, and the volume of water displaced is equal to the volume of the object. The mass is measured using a balance, and the density can then be calculated.

-

Water Displacement with Regularly Shaped Objects: For objects with regular shapes (cubes, cylinders, etc.), the volume can be calculated directly using standard geometric formulas. The mass is measured, and the density is calculated as mass/volume.

-

Pycnometry: This method employs a precise instrument called a pycnometer to measure the volume of a sample with high accuracy. The pycnometer is filled with a known volume of liquid, and the sample is then added. The difference in volume provides the volume of the sample.

These experimental methods are crucial for quality control in industrial settings and research purposes, ensuring that the aluminum used meets the required specifications.

Conclusion: The Importance of Understanding Aluminum Density

The density of aluminum is a fundamental property that directly impacts its suitability for a myriad of applications. Understanding the typical density of pure aluminum (2.70 g/cm³) and the factors that can cause variations, such as alloying elements and temperature, is crucial for engineers, designers, and anyone working with this versatile metal. Whether designing an airplane, constructing a building, or packaging a beverage, awareness of aluminum's density is integral to optimizing performance, minimizing weight, and ensuring product quality. Precise density measurement techniques are vital for quality control and research, reinforcing the significance of this seemingly simple physical property in shaping our modern world.

Latest Posts

Latest Posts

-

Genes Had Been Absent On The Chromosomes

Mar 28, 2025

-

Which Of The Following Is A Nonrenewable Source Of Energy

Mar 28, 2025

-

An Improvement In Production Technology Will

Mar 28, 2025

-

If 2 X 1 14 Then X

Mar 28, 2025

-

How Many Mm Are In 50 Cm

Mar 28, 2025

Related Post

Thank you for visiting our website which covers about What Is The Density Of Aluminium . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.