Is Ductility A Physical Or Chemical Property

News Leon

Mar 18, 2025 · 5 min read

Table of Contents

Is Ductility a Physical or Chemical Property? A Deep Dive

Ductility, the ability of a material to deform under tensile stress, is a fundamental property explored in materials science and engineering. Understanding whether it's a physical or chemical property is crucial for selecting materials for various applications. This in-depth article will dissect the nature of ductility, exploring its definition, differentiating it from other properties, and definitively answering the core question: is ductility a physical or chemical property?

Understanding Ductility: Definition and Significance

Ductility is defined as a material's ability to undergo significant plastic deformation before fracture under tensile stress. Essentially, it's how much a material can be stretched or drawn into a wire before breaking. This property is visually striking – think of the malleability of gold, easily hammered and shaped, or the drawn-out wires of copper used in electrical applications.

The significance of ductility cannot be overstated. It dictates a material's suitability for various applications:

- Manufacturing Processes: Ductile materials are essential in processes like wire drawing, rolling, extrusion, and forging. These processes rely on the material's ability to deform plastically without fracturing.

- Structural Applications: In structural engineering, ductility is crucial for absorbing energy during impacts or seismic events. Ductile materials can deform significantly before failure, preventing catastrophic collapse.

- Design Considerations: Designers consider ductility when selecting materials for components subjected to tensile forces. A ductile material will offer greater tolerance for stress concentrations and unforeseen loads.

Ductility vs. Malleability: A Key Distinction

While often used interchangeably, ductility and malleability represent distinct aspects of a material's behavior under stress.

- Ductility refers to a material's ability to be drawn into wires. It's essentially a measure of its tensile deformability.

- Malleability describes a material's ability to be hammered or rolled into sheets. This refers to its compressive deformability.

Both properties indicate plasticity – the ability to undergo permanent deformation – but they involve different types of stress and deformation modes. A material can be highly ductile but less malleable, or vice versa, depending on its crystal structure and bonding characteristics.

The Physical Nature of Ductility

Ductility is unequivocally a physical property. This is because it describes a material's behavior in response to an external force without altering its chemical composition. The process of stretching or drawing a ductile material does not change its elemental makeup or molecular structure.

Consider the following:

- No Chemical Reactions: When stretching a copper wire, no chemical reactions occur. The copper atoms are simply rearranged, altering the material's shape but not its chemical identity.

- Reversible Deformation (Elasticity): While ductility describes plastic deformation (permanent), the initial stages of stretching involve elastic deformation, which is completely reversible. Upon removal of the tensile stress, the material returns to its original shape. This further reinforces its physical nature.

- Observable and Measurable: Ductility can be easily observed and quantified through tensile tests, providing objective measurements of elongation and reduction in area. These measurements are purely physical, not chemical.

Factors Influencing Ductility

Several factors significantly influence a material's ductility:

- Crystal Structure: Materials with face-centered cubic (FCC) crystal structures, like copper and aluminum, generally exhibit high ductility due to the ease of dislocation movement. Body-centered cubic (BCC) structures, such as iron, tend to be less ductile at lower temperatures.

- Grain Size: Smaller grain sizes often lead to enhanced ductility as grain boundaries impede dislocation movement, reducing the likelihood of crack propagation.

- Temperature: Temperature plays a vital role. Many materials become more ductile at higher temperatures, as increased thermal energy facilitates dislocation motion.

- Impurities and Alloying: The presence of impurities or alloying elements can significantly affect ductility. Some impurities can strengthen the material, reducing ductility, while others might enhance it.

- Strain Rate: The rate at which the material is deformed affects its ductility. Faster strain rates tend to decrease ductility, as less time is available for dislocation movement and stress relaxation.

Differentiating Ductility from Chemical Properties

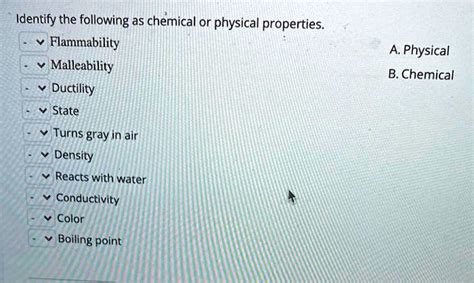

Chemical properties describe a substance's ability to undergo a chemical change, transforming its composition. Examples include flammability, reactivity with acids, and oxidation potential. Ductility, conversely, involves only a change in shape without altering the substance's chemical identity.

Here's a table summarizing the key differences:

| Feature | Ductility (Physical) | Chemical Property (e.g., Reactivity) |

|---|---|---|

| Change Involved | Shape change, no change in chemical composition | Change in chemical composition, formation of new substances |

| Process | Deformation under stress | Chemical reaction |

| Reversibility | Partially reversible (elastic deformation) | Typically irreversible |

| Measurement | Elongation, reduction in area | Reaction rate, product formation, etc. |

Ductility in Different Materials

The ductility of a material is highly dependent on its composition and microstructure.

- Metals: Metals generally display varying degrees of ductility, with FCC metals exhibiting the highest levels. However, even within metal families, significant differences exist; some steel alloys possess high ductility, while others are brittle.

- Ceramics: Ceramics are typically brittle and possess very low ductility. Their strong ionic or covalent bonds resist plastic deformation.

- Polymers: Polymers can exhibit a wide range of ductility, depending on their molecular weight, structure, and processing conditions. Some polymers can be highly ductile, while others are brittle.

- Composites: The ductility of composite materials depends on the properties of their constituent phases and their interaction.

Conclusion: Ductility – A Defining Physical Characteristic

In conclusion, ductility is unequivocally a physical property. It describes a material's response to external forces without involving any change in its chemical composition. Its importance spans diverse fields, from manufacturing and engineering to material design. Understanding the factors influencing ductility is crucial for selecting appropriate materials for specific applications, optimizing processes, and ensuring structural integrity. While related properties like malleability exist, ductility's focus on tensile deformation sets it apart, making it an indispensable concept in materials science. Therefore, clarifying its physical nature allows for a more precise understanding of material behavior and design capabilities.

Latest Posts

Latest Posts

-

Which Chamber Of Heart Has Thickest Wall

Mar 18, 2025

-

How Many Feet Is 1 2 Miles

Mar 18, 2025

-

How Many Valence Electrons Does Mn Have

Mar 18, 2025

-

Lines Of Symmetry On A Trapezoid

Mar 18, 2025

-

Two Same Words With Different Meanings

Mar 18, 2025

Related Post

Thank you for visiting our website which covers about Is Ductility A Physical Or Chemical Property . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.