Difference Between Ac Motor And Dc Motor

News Leon

Mar 24, 2025 · 6 min read

Table of Contents

- Difference Between Ac Motor And Dc Motor

- Table of Contents

- AC Motor vs. DC Motor: A Deep Dive into the Differences

- Fundamental Differences: AC vs. DC Power Supply

- AC Motor: The Alternating Current Powerhouse

- DC Motor: The Direct Current Workhorse

- A Comparative Table: Key Differences at a Glance

- Choosing the Right Motor: Application Considerations

- Conclusion: The Reign of Both AC and DC Motors

- Latest Posts

- Latest Posts

- Related Post

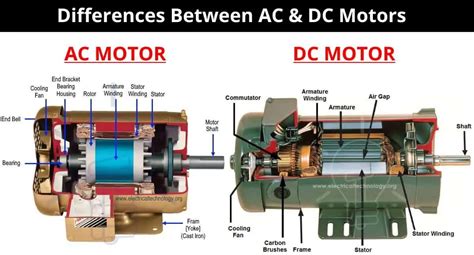

AC Motor vs. DC Motor: A Deep Dive into the Differences

The world of electric motors is vast and complex, populated by a diverse array of technologies. However, two types stand out above the rest in terms of prevalence and application: AC motors and DC motors. While both achieve the same fundamental goal – converting electrical energy into mechanical energy – their underlying operating principles, construction, and characteristics differ significantly. Understanding these differences is crucial for selecting the right motor for a specific application. This comprehensive guide will delve into the intricacies of AC and DC motors, highlighting their key distinctions, advantages, and disadvantages.

Fundamental Differences: AC vs. DC Power Supply

The most fundamental difference lies in their power source: AC (Alternating Current) motors operate using alternating current, characterized by its sinusoidal waveform that constantly changes direction. DC (Direct Current) motors, on the other hand, run on direct current, a unidirectional flow of electrons. This seemingly simple distinction leads to a cascade of differences in their design, operation, and applications.

AC Motor: The Alternating Current Powerhouse

AC motors are ubiquitous, powering everything from industrial machinery to household appliances. Their prevalence is largely due to the ease of generating and transmitting AC power over long distances, making them cost-effective for widespread use. Several types of AC motors exist, each with its own unique characteristics:

-

Induction Motors (Asynchronous Motors): These are the most common type of AC motor, known for their robust construction, simple design, and low maintenance requirements. They rely on the principle of electromagnetic induction to create torque. A rotating magnetic field in the stator induces current in the rotor, creating a magnetic field that interacts with the stator's field, resulting in rotation. Induction motors are further categorized into squirrel-cage and wound-rotor types, differing in their rotor construction and starting characteristics.

-

Synchronous Motors: These motors operate at a constant speed synchronized with the frequency of the AC power supply. They require a separate excitation source to create the rotor magnetic field, offering precise speed control and high efficiency at rated loads. Synchronous motors are frequently used in applications demanding constant speed, such as clocks and timing devices.

-

Stepper Motors: These motors provide precise angular movements in discrete steps. They are controlled digitally and are widely used in robotics, automation, and 3D printing. Stepper motors offer high accuracy and precise positioning but typically have lower torque compared to induction or synchronous motors.

Advantages of AC Motors:

- Robust and Durable: Generally less susceptible to wear and tear, requiring minimal maintenance.

- Cost-Effective: Widely manufactured, making them relatively inexpensive.

- High Power Output: Capable of delivering high torque and power, suitable for heavy-duty applications.

- Easy to Maintain: Simple design minimizes maintenance requirements and downtime.

Disadvantages of AC Motors:

- Speed Control Limitations: Precise speed control can be challenging, especially for induction motors. Speed control often involves using variable frequency drives (VFDs), adding to the cost and complexity.

- Starting Torque: Some AC motors, particularly induction motors, may exhibit relatively low starting torque.

- Power Factor: Induction motors can have a lagging power factor, requiring power factor correction capacitors to improve efficiency.

DC Motor: The Direct Current Workhorse

DC motors, while less prevalent than AC motors in certain applications, offer advantages in specific scenarios. They utilize the interaction between a magnetic field and current-carrying conductors to produce rotational motion. Several types of DC motors exist, each with unique characteristics:

-

Brushed DC Motors: These motors use brushes to conduct current to the commutator, which in turn directs current to the rotor windings. They are relatively simple and inexpensive, offering good starting torque and speed control. However, the brushes wear out over time, requiring periodic replacement and maintenance.

-

Brushless DC Motors (BLDC): These motors eliminate the need for brushes, using electronic commutation instead. This results in significantly longer lifespan, higher efficiency, reduced maintenance, and quieter operation. However, they are generally more complex and expensive than brushed DC motors. They are often used in applications demanding high precision and longevity, like drones, electric vehicles, and computer fans.

-

Permanent Magnet DC Motors: These motors use permanent magnets to create the magnetic field, eliminating the need for field windings. They are simple, compact, and efficient, commonly found in smaller appliances and toys.

Advantages of DC Motors:

- Precise Speed Control: Easier to control speed and torque compared to AC motors, often using simple electronic circuits.

- High Starting Torque: Generally offer higher starting torque than AC motors, especially brushed DC motors.

- Simple Control: Relatively straightforward to control speed and direction.

Disadvantages of DC Motors:

- Maintenance: Brushed DC motors require regular brush replacement, increasing maintenance costs.

- Cost: Brushless DC motors, while offering superior performance, can be more expensive than AC motors.

- Commutation Issues: Brushed DC motors can experience sparking and wear at the commutator.

A Comparative Table: Key Differences at a Glance

| Feature | AC Motor | DC Motor |

|---|---|---|

| Power Supply | Alternating Current (AC) | Direct Current (DC) |

| Construction | More complex, often requiring specialized components | Can be simpler, though brushless DC motors are complex |

| Speed Control | More challenging, often requires VFDs | Easier to control, often using simple electronics |

| Starting Torque | Can be low, depending on type | Generally higher |

| Maintenance | Generally low | Higher for brushed DC motors, lower for brushless |

| Cost | Generally lower | Can be higher, especially for brushless types |

| Efficiency | Can be high, particularly with synchronous motors | Can be high, especially with brushless types |

| Applications | Industrial machinery, household appliances | Robotics, automotive, appliances, tools |

Choosing the Right Motor: Application Considerations

The choice between an AC and DC motor depends heavily on the specific application requirements. Here's a breakdown of factors to consider:

-

Power Requirements: High-power applications often favor AC motors due to their robustness and efficiency at higher power levels. DC motors are well-suited for lower-power applications.

-

Speed Control Needs: If precise speed control is crucial, DC motors, especially brushless types, are preferred. AC motors, while controllable, often require more complex and expensive solutions.

-

Torque Requirements: Applications needing high starting torque often benefit from DC motors.

-

Environmental Conditions: AC motors are generally more robust and can tolerate harsher environmental conditions compared to some DC motors.

-

Cost and Maintenance: AC motors tend to be more cost-effective initially, while the long-term cost of maintenance is typically lower. Brushless DC motors, while initially expensive, offer lower maintenance costs in the long run.

-

Size and Weight: Certain applications may favor smaller and lighter motors, potentially leading to the selection of a DC motor.

Conclusion: The Reign of Both AC and DC Motors

While the world of electric motors may seem dominated by AC motors due to their widespread use, both AC and DC motors occupy crucial niches. AC motors excel in high-power, industrial applications where robust construction and cost-effectiveness are paramount. DC motors, especially brushless DC motors, shine in applications needing precise speed and torque control, quieter operation, and extended lifespan. The optimal choice always hinges on a thorough analysis of the specific application requirements, considering factors like power needs, control demands, environmental factors, and the overall cost-benefit equation. Understanding the fundamental differences between AC and DC motors empowers engineers and designers to select the most appropriate motor for any given task, maximizing efficiency, performance, and longevity.

Latest Posts

Latest Posts

-

Difference Between Liquid And Aqueous Solution

Mar 27, 2025

-

In Part A Of The Figure An Electron Is Shot

Mar 27, 2025

-

Which Colony Did Not Attend The First Continental Congress

Mar 27, 2025

-

What Organelles Contain Their Own Dna

Mar 27, 2025

-

How Far Is 3000 Feet To Walk

Mar 27, 2025

Related Post

Thank you for visiting our website which covers about Difference Between Ac Motor And Dc Motor . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.