A Water Intake At A Pump Storage Reservoir

News Leon

Mar 21, 2025 · 6 min read

Table of Contents

A Water Intake at a Pump Storage Reservoir: Design, Operation, and Maintenance

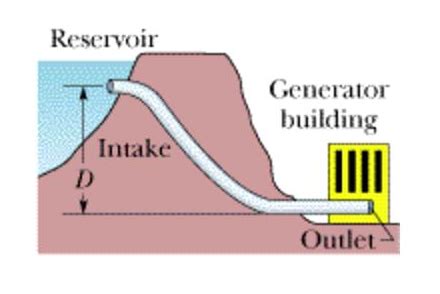

Pumped hydro storage (PHS) plants are a crucial component of a reliable and sustainable energy future. They offer a flexible and efficient way to store excess energy generated from renewable sources like solar and wind, releasing it when demand is high. At the heart of every PHS plant lies the pump storage reservoir, and within that reservoir, a critical piece of infrastructure: the water intake. This article delves deep into the design, operation, and maintenance of water intakes in pump storage reservoirs, highlighting the crucial role they play in the overall efficiency and longevity of the power generation system.

Understanding the Role of a Water Intake in a Pump Storage Reservoir

The water intake structure serves as the gateway for water flowing from the upper reservoir to the powerhouse during power generation. It's a complex system engineered to handle significant volumes of water under varying conditions, efficiently delivering it to the turbines while minimizing losses and ensuring consistent power output. Its design considerations go far beyond simply channeling water; it must also address factors like:

Sediment Control:

- Sedimentation is a major concern. Over time, sediment carried by the water can accumulate within the intake structure, reducing its efficiency and potentially causing damage. This requires careful design features to minimize sediment entry and facilitate regular cleaning. Screens, settling basins, and flushing systems are commonly employed.

- The type and quantity of sediment vary widely based on location. Upstream land use, geology, and hydrological conditions all dictate the appropriate sediment management strategy. Detailed site-specific studies are crucial during the design phase.

Debris Management:

- Large debris, such as logs, branches, and even animals, can severely hinder or completely block the intake. Efficient debris removal systems are essential, often incorporating trash racks, traveling screens, and automated cleaning mechanisms. Regular inspections and maintenance are critical to prevent blockages.

- The design of debris removal systems is a balance between efficiency and ease of maintenance. Complex systems may be more effective but also more costly and time-consuming to operate and repair.

Water Level Fluctuations:

- Pump storage reservoirs experience significant water level variations. The intake structure must accommodate these fluctuations without compromising its integrity or operational efficiency. Designs often include submerged inlets or adjustable gates to maintain optimal flow regardless of reservoir level.

- The design must consider extreme conditions, such as during periods of drought or exceptionally heavy rainfall, to ensure the intake remains functional.

Intake Structure Materials:

- Material selection is vital for durability and resistance to corrosion and erosion. Concrete, stainless steel, and various specialized alloys are commonly used, chosen based on factors like water chemistry, environmental conditions, and expected lifespan.

- The chosen materials must be compatible with the surrounding environment to prevent chemical reactions and ecological damage.

Hydraulic Considerations:

- The intake structure is designed to optimize water flow to the turbines. This involves careful consideration of the inlet's geometry, the use of flow-control devices, and the minimization of head loss. Sophisticated computational fluid dynamics (CFD) modeling is often used to optimize the design.

- Understanding the hydraulics of the intake structure is key to maximizing the efficiency of the power generation process. Even small inefficiencies can translate to significant losses in power output over the lifetime of the plant.

Design Considerations for a Water Intake at a Pump Storage Reservoir

The design of a water intake for a PHS plant is a multifaceted process, requiring expertise in various engineering disciplines, including hydraulics, civil engineering, and materials science. Key design aspects include:

Location and Accessibility:

- The intake's location is chosen strategically to minimize construction costs and ensure efficient water flow. This involves geological surveys, environmental impact assessments, and careful consideration of accessibility for maintenance and repairs.

- Accessibility is crucial for maintenance and repair. A location that is difficult to reach can significantly increase maintenance costs and downtime.

Intake Structure Type:

- Several types of intake structures exist, each with its advantages and disadvantages. These include:

- Vertical shaft intakes: Common for deep reservoirs, they offer efficient sediment control and minimize water surface disturbance.

- Horizontal intakes: Suitable for shallower reservoirs, they may be less expensive to construct but might be more susceptible to sediment accumulation.

- Multiple intake structures: Used in large reservoirs to distribute the water load and provide redundancy.

Gate and Valve Systems:

- Gate and valve systems are essential for controlling water flow. These can include sluice gates, butterfly valves, and other types of flow-control devices. Their design and placement are crucial to maintaining optimal flow while preventing damage from excessive pressure or flow.

- Regular maintenance and inspection of gate and valve systems are paramount to avoid failure and ensure safe operation.

Instrumentation and Control:

- A comprehensive instrumentation and control system is essential for monitoring the intake's performance and ensuring safe operation. This typically includes level sensors, flow meters, pressure sensors, and various other monitoring devices. Automated control systems can optimize water flow and prevent damage.

- Data acquisition and analysis are crucial for optimizing intake performance and identifying potential problems early.

Operation and Maintenance of the Water Intake

The ongoing operation and maintenance of the water intake are vital to ensure the long-term efficiency and reliability of the PHS plant. This involves:

Regular Inspections:

- Frequent inspections are critical to identify potential problems early. This includes visual inspections of the structure, gates, and other components, as well as monitoring of instrumentation data. Inspections should be performed at intervals tailored to the specific design and operating conditions.

- Regular inspections ensure any necessary maintenance is completed promptly, preventing minor issues from becoming major problems.

Cleaning and Debris Removal:

- Regular cleaning is necessary to remove accumulated sediment and debris. This may involve manual cleaning, use of automated cleaning systems, or a combination of both. Cleaning frequency depends on the reservoir's characteristics and sediment load.

- Effective debris removal systems are essential for preventing blockages and maintaining efficient water flow to the turbines.

Gate and Valve Maintenance:

- Gate and valve systems require regular lubrication, inspection, and testing. This ensures their proper functioning and prevents damage from corrosion or wear. Regular maintenance also extends the lifespan of these critical components.

- Testing valve systems at regular intervals is important to guarantee their proper operation and to ensure they can handle the required flow rates.

Instrumentation and Control System Maintenance:

- The instrumentation and control system requires calibration and maintenance to ensure accurate data acquisition and reliable operation. This includes periodic testing of sensors, controllers, and communication systems.

- Maintaining the instrumentation and control system is critical for maintaining safe and efficient operation. It allows for early detection of potential problems.

Emergency Procedures:

- Well-defined emergency procedures are crucial to address unexpected situations, such as equipment failure or unexpected debris accumulation. These procedures should cover actions to be taken to protect equipment, minimize downtime, and ensure personnel safety.

- Regular drills should be conducted to ensure staff are adequately trained to respond effectively to emergency situations.

Conclusion: Ensuring the Long-Term Performance of Pump Storage Reservoirs

The water intake at a pump storage reservoir is a critical piece of infrastructure that plays a vital role in the efficiency and reliability of the entire power generation system. Careful design consideration, coupled with rigorous operation and maintenance procedures, are crucial to ensure its long-term performance and the sustainable operation of the pumped hydro storage plant. By incorporating advanced technologies and adopting proactive maintenance strategies, operators can maximize the lifespan and efficiency of these crucial components, contributing to a more sustainable and reliable energy future. Ongoing research and innovation in materials science, hydraulic engineering, and automated control systems promise to further enhance the design, operation, and maintenance of water intakes in pump storage reservoirs, paving the way for even more efficient and sustainable energy generation.

Latest Posts

Latest Posts

-

Is It Better To Write Zn2 Or Zn 2

Mar 21, 2025

-

Which Of The Following Is Always True

Mar 21, 2025

-

How Many Four Digit Numbers Are There

Mar 21, 2025

-

Calculate The Molarity Of Each Of The Following Solutions

Mar 21, 2025

-

In The Figure A Metal Wire Of Mass

Mar 21, 2025

Related Post

Thank you for visiting our website which covers about A Water Intake At A Pump Storage Reservoir . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.