A Parallel-plate Capacitor Has Circular Plates

News Leon

Mar 19, 2025 · 6 min read

Table of Contents

A Parallel-Plate Capacitor with Circular Plates: A Deep Dive into Capacitance and Applications

A parallel-plate capacitor, a fundamental component in electronics, consists of two conductive plates separated by a dielectric material. When a voltage is applied across the plates, charge accumulates, storing electrical energy. While often simplified to rectangular plates in introductory physics, many real-world applications utilize capacitors with circular plates. This article delves into the intricacies of a parallel-plate capacitor with circular plates, exploring its capacitance, applications, and the factors influencing its performance.

Understanding Capacitance in Circular Parallel-Plate Capacitors

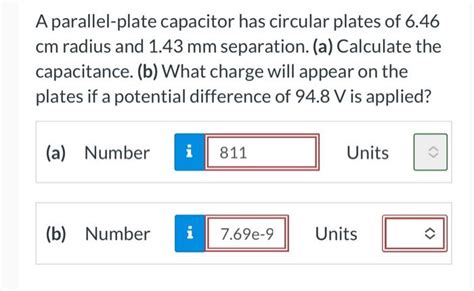

The capacitance (C) of a capacitor, a measure of its ability to store charge, is directly proportional to the area (A) of the plates and the permittivity (ε) of the dielectric material, and inversely proportional to the separation distance (d) between the plates. The formula for capacitance is:

C = εA/d

However, this simple formula applies directly only to capacitors with perfectly uniform electric fields between parallel plates, such as those with rectangular plates. For circular plates, the electric field is non-uniform near the edges, leading to a slightly more complex calculation. The fringe effects, as these edge effects are known, become increasingly significant as the plate separation (d) approaches the plate radius (r).

The Impact of Fringe Effects

The non-uniform electric field at the edges of the circular plates means the simple formula above provides only an approximation. The actual capacitance will be slightly higher than the value calculated using the formula. This difference becomes more pronounced as the ratio of d/r increases.

Several methods exist to account for fringe effects, including:

-

Finite Element Analysis (FEA): A powerful numerical technique used to simulate the electric field distribution and calculate the capacitance with high accuracy. FEA considers the complex geometry and material properties to provide precise capacitance values, accounting for all edge effects.

-

Approximation Formulas: Various approximate formulas have been developed to correct the simple formula for circular plates. These formulas often incorporate correction factors that depend on the ratio of d/r, providing a more accurate capacitance value than the basic equation. One common approximation involves adding a "fringe capacitance" term to the basic formula.

-

Experimental Measurement: Direct measurement of capacitance using a capacitance meter provides the most accurate capacitance value for a specific capacitor. This method bypasses the need for complex calculations or approximations, although it requires access to appropriate testing equipment.

Calculating Capacitance with Corrections for Fringe Effects

While an exact analytical solution for the fringe effects remains elusive, various approximations exist. These approximations generally refine the basic capacitance equation by adding a correction factor:

C ≈ εA/d + C<sub>fringe</sub>

where C<sub>fringe</sub> represents the additional capacitance due to fringe effects. The precise form of C<sub>fringe</sub> depends on the approximation method used.

Dielectric Material and its Influence

The dielectric material inserted between the capacitor plates significantly affects the capacitance. The permittivity (ε) of the dielectric material is a measure of its ability to store electrical energy within its electric field. A higher permittivity dielectric leads to a higher capacitance for the same geometry. Common dielectric materials include:

-

Air: A low-permittivity dielectric, often used in variable capacitors where precise capacitance adjustment is crucial.

-

Ceramic: Offers a high permittivity, making it suitable for applications requiring high capacitance density.

-

Mica: A high-quality dielectric with excellent stability and low dielectric losses, commonly used in high-frequency applications.

-

Polymers (e.g., Teflon, polyethylene): Provide a range of permittivity values and are used in different applications based on the desired capacitance and operating frequency.

The choice of dielectric material is crucial, impacting not only the capacitance value but also the capacitor's operating temperature range, voltage rating, and overall performance.

Applications of Circular Parallel-Plate Capacitors

The unique geometry of circular parallel-plate capacitors makes them well-suited for specific applications:

1. Variable Capacitors

Circular plates allow for mechanical rotation of one plate relative to the other, effectively changing the overlapping area (A). This configuration is commonly used in radio tuning circuits, allowing for continuous adjustment of the capacitance and thus the resonant frequency.

2. High-Frequency Applications

The relatively large surface area of circular plates for a given plate separation makes them suitable for high-frequency applications where high capacitance is often required to handle large currents at high speeds. Additionally, minimizing parasitic inductance and capacitance are important in high-frequency circuits.

3. Microelectronics and MEMS Devices

Miniaturized versions of circular parallel-plate capacitors are used in microelectronics and Microelectromechanical Systems (MEMS) devices. Their relatively simple fabrication process and ability to integrate easily into microchips make them ideal components in these applications. Here, the accurate calculation of the capacitance, accounting for fringe effects, becomes crucial for the precise performance of the integrated circuit.

4. Sensors and Transducers

The change in capacitance due to variations in the dielectric material, plate separation, or overlapping area can be used to measure various physical quantities. This forms the basis of many capacitive sensors, such as those measuring displacement, pressure, or humidity. The circular geometry can provide a consistent and predictable response across different measurements.

5. Energy Storage

Although not the primary energy storage method, parallel plate capacitors, including circular ones, still find applications in energy storage. For instance, in pulsed power systems or energy harvesting applications requiring a burst of energy, these capacitors can efficiently store and deliver a controlled discharge.

Factors Affecting Performance and Design Considerations

Several factors influence the performance of a circular parallel-plate capacitor:

-

Plate Separation (d): A smaller separation distance (d) leads to a higher capacitance, but also increases the risk of dielectric breakdown, limiting the voltage rating of the capacitor.

-

Plate Radius (r): A larger radius increases the capacitance, but also increases the size and cost of the capacitor.

-

Dielectric Material: The choice of dielectric material greatly influences the capacitance, voltage rating, and temperature stability.

-

Frequency: At high frequencies, the parasitic inductance and capacitance of the capacitor's leads and connections become significant, affecting the overall performance.

-

Temperature: The capacitance value can vary slightly with temperature, especially for certain dielectric materials.

Careful consideration of these factors is essential during the design and selection of circular parallel-plate capacitors to ensure optimal performance in the intended application.

Conclusion

Circular parallel-plate capacitors, while seemingly a simple variation on the standard parallel-plate design, present unique challenges and opportunities. The non-uniform electric field near the edges necessitates the consideration of fringe effects for accurate capacitance calculation. However, the ability to easily adjust capacitance mechanically and their suitability for miniaturization make them indispensable components in a wide array of applications, from radio tuning to microelectronics and sensing. By understanding the underlying physics and the various factors influencing performance, engineers can effectively design and utilize these capacitors for optimal functionality in diverse electronic systems. The continued advancements in materials science and fabrication techniques promise even more sophisticated and efficient circular parallel-plate capacitors in the future.

Latest Posts

Latest Posts

-

Why Was Reagan Called The Teflon President

Mar 20, 2025

-

Naoh Was Added To A 7 75

Mar 20, 2025

-

How Many Chambers Does Fish Heart Have

Mar 20, 2025

-

What Is 90 Degree Celsius In Fahrenheit

Mar 20, 2025

-

Vitamin A Is Necessary For The Synthesis Of Rhodopsin

Mar 20, 2025

Related Post

Thank you for visiting our website which covers about A Parallel-plate Capacitor Has Circular Plates . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.