A Parallel Plate Air Filled Capacitor Having Area

News Leon

Mar 22, 2025 · 7 min read

Table of Contents

A Parallel Plate Air-Filled Capacitor: A Deep Dive into Capacitance and its Applications

The humble parallel plate capacitor, especially when filled with air, serves as a foundational component in electronics and electromagnetism. Understanding its behavior is crucial for anyone working with circuits, signal processing, or even high-energy physics. This comprehensive guide delves into the intricacies of a parallel plate air-filled capacitor, exploring its capacitance, energy storage, applications, and limitations.

Understanding Capacitance

Capacitance, denoted by C, is a measure of a capacitor's ability to store electrical energy. It quantifies the amount of charge (Q) a capacitor can store for a given voltage (V) across its plates. The fundamental relationship is given by:

Q = CV

The unit of capacitance is the farad (F), which represents a large capacitance. More commonly, we encounter microfarads (µF), nanofarads (nF), and picofarads (pF).

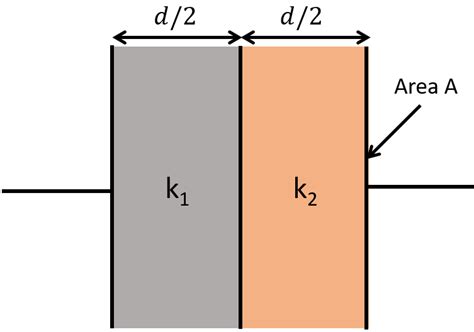

The Parallel Plate Capacitor: Geometry and Capacitance

A parallel plate capacitor consists of two conductive plates separated by a dielectric material. In our case, the dielectric is air. The capacitance of a parallel plate air-filled capacitor is directly proportional to the area (A) of the plates and inversely proportional to the distance (d) separating them. This relationship is expressed as:

C = ε₀A/d

Where:

- C is the capacitance in farads (F)

- ε₀ is the permittivity of free space (approximately 8.854 x 10⁻¹² F/m)

- A is the area of each plate in square meters (m²)

- d is the distance between the plates in meters (m)

This equation highlights the importance of plate area and separation distance in determining the capacitor's capacitance. A larger plate area results in higher capacitance, allowing for greater charge storage at a given voltage. Conversely, increasing the separation distance decreases the capacitance.

The Role of the Dielectric (Air)

While air might seem like a simple dielectric, its permittivity (ε₀) plays a crucial role in determining the capacitor's capacitance. The permittivity of a material represents its ability to store electrical energy within an electric field. Air's permittivity is relatively low compared to other dielectric materials like ceramics or plastics. This low permittivity is why air-filled capacitors generally have lower capacitance values for a given plate area and separation distance.

Impact of Plate Area (A)

The area of the capacitor plates directly impacts the capacitance. A larger plate area means more charge can be stored on the plates for a given voltage. This is because a larger area provides more surface for charge accumulation. Consider a scenario where you double the plate area. According to the formula, the capacitance will also double, allowing for twice the charge storage at the same voltage.

Influence of Plate Separation (d)

The distance between the plates is inversely proportional to the capacitance. As the distance increases, the capacitance decreases. This is because the electric field lines between the plates become less concentrated, weakening the ability of the capacitor to store charge. If you double the plate separation distance, the capacitance will be halved. This highlights the importance of precise manufacturing tolerances when creating air-filled capacitors. Even slight variations in the separation distance can noticeably affect capacitance.

Energy Storage in a Parallel Plate Capacitor

A capacitor stores energy in the electric field between its plates. The energy (U) stored in a capacitor is given by:

U = 1/2 CV² = 1/2 QV = Q²/2C

This equation shows that the stored energy is proportional to both the capacitance and the square of the voltage. Therefore, increasing the voltage across a capacitor significantly increases the stored energy.

Practical Implications of Energy Storage

Understanding energy storage is critical in many applications. For instance, in flash photography, a capacitor stores a significant amount of energy that is quickly discharged to create a bright flash. Similarly, in power supplies, capacitors smooth out voltage fluctuations, providing a stable voltage to the circuit.

Applications of Air-Filled Capacitors

Despite their relatively low capacitance compared to other types of capacitors, air-filled capacitors find niche applications where their unique properties are advantageous:

High-Frequency Applications:

Air's low dielectric losses make air-filled capacitors ideal for high-frequency applications. Other dielectric materials can exhibit significant energy losses at high frequencies, leading to inefficient operation. Air-filled capacitors maintain their performance and minimize energy loss even at high frequencies. This is particularly important in radio frequency (RF) circuits and high-speed electronics.

High-Voltage Applications:

Air has a high breakdown voltage, meaning it can withstand a higher electric field before dielectric breakdown occurs. This makes air-filled capacitors suitable for high-voltage applications where other dielectric materials might fail. This is crucial in high-voltage power systems and specialized electrical equipment.

Variable Capacitors:

Air-filled variable capacitors are used in tuning circuits for radio receivers and other applications requiring adjustable capacitance. By mechanically varying the distance between the plates or the overlapping area of the plates, the capacitance can be changed, allowing for precise tuning of resonant frequencies. This mechanical adjustability makes them essential in radio frequency (RF) circuits where precise frequency selection is necessary.

Precision Capacitance Standards:

Due to their predictable and stable capacitance, air-filled capacitors are sometimes employed as precision capacitance standards in calibration laboratories. The lack of a solid dielectric material eliminates the uncertainty associated with the dielectric constant's temperature dependence, thus providing greater accuracy in measurements.

Limitations of Air-Filled Capacitors

While air-filled capacitors have their advantages, they also possess limitations:

Low Capacitance:

Their most significant limitation is their relatively low capacitance. To achieve even moderate capacitance values, air-filled capacitors often require large plate areas or extremely small plate separations. This can result in bulky designs and manufacturing challenges.

Environmental Sensitivity:

Air's permittivity can be slightly affected by changes in temperature, pressure, and humidity. Although the effect is typically minor, these variations can slightly affect the capacitor's capacitance in precision applications.

Susceptibility to Arcing:

At high voltages, air can ionize, leading to arcing between the plates. This arcing can damage the capacitor and disrupt its functionality. Careful design and proper voltage ratings are crucial to prevent arcing in high-voltage applications.

Mechanical Robustness:

Air-filled capacitors are often less mechanically robust than those using solid dielectric materials. The large plate separation required for a reasonable capacitance makes them more susceptible to damage from physical shock or vibration.

Design Considerations for Air-Filled Capacitors

Designing air-filled capacitors involves careful consideration of several factors:

-

Plate Material: The choice of plate material is critical. Materials with high conductivity and low resistance are essential to minimize energy losses. Common choices include copper, aluminum, and brass.

-

Plate Shape and Geometry: The shape and geometry of the plates significantly influence the electric field distribution and capacitance. Parallel plates are the most common design, but other geometries can offer advantages in specific applications.

-

Plate Separation: Maintaining a precise and consistent plate separation is vital for accurate capacitance control. This requires precise manufacturing techniques.

-

Environmental Protection: Air-filled capacitors might need protection against moisture, dust, and other environmental contaminants that could affect their performance. Enclosures or sealing techniques might be necessary, especially in demanding environments.

-

Voltage Rating: The voltage rating of the capacitor should be carefully chosen to prevent arcing and ensure safe operation. It's crucial to select a voltage rating well above the expected operating voltage.

Conclusion

Parallel plate air-filled capacitors, while seemingly simple, are indispensable components in various electronic and electromechanical systems. Their characteristics, including high-frequency performance, high-voltage tolerance, and adjustable capacitance, make them valuable in specific applications. However, their low capacitance and susceptibility to environmental factors should be considered during the design process. A thorough understanding of their properties and limitations is vital for engineers and designers working with these fundamental components. Through careful design and material selection, these limitations can often be mitigated, unlocking the full potential of air-filled capacitors in numerous applications.

Latest Posts

Latest Posts

-

1 Gram Of Carbohydrate Yields Approximately 9 Kcal Of Energy

Mar 23, 2025

-

Guanine Forms Hydrogen Bonds With Cytosine

Mar 23, 2025

-

A Quadrilateral Where Each Angle Is A Right Angle

Mar 23, 2025

-

Shape With 12 Edges And 6 Faces

Mar 23, 2025

-

48 Hours Is Equal To How Many Days

Mar 23, 2025

Related Post

Thank you for visiting our website which covers about A Parallel Plate Air Filled Capacitor Having Area . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.