The Resistivity Of A Wire Depends On

News Leon

Mar 26, 2025 · 6 min read

Table of Contents

The Resistivity of a Wire Depends On: A Deep Dive into Electrical Resistance

Understanding the resistance of a wire is fundamental to numerous fields, from electrical engineering and electronics to material science and physics. This resistance, a measure of how much a material opposes the flow of electric current, isn't simply a fixed property of the wire itself. Instead, it's intricately linked to several factors. This article will delve deep into these dependencies, providing a comprehensive explanation of how each parameter affects the resistivity of a wire.

1. Material: The Intrinsic Resistance

The most significant factor determining a wire's resistivity is its material. Different materials possess different atomic structures and electron configurations, leading to vastly different abilities to conduct electricity. This inherent property is quantified by resistivity (ρ), measured in ohm-meters (Ω·m).

Understanding Resistivity

Resistivity is a measure of a material's resistance to the flow of current per unit length and cross-sectional area. A high resistivity indicates a material is a poor conductor (e.g., rubber), while a low resistivity indicates a good conductor (e.g., copper). This intrinsic property is largely determined by:

-

Electron Mobility: Materials with a high number of free electrons and high electron mobility (ease of movement) exhibit lower resistivity. Metals, with their freely moving valence electrons, are prime examples.

-

Atomic Structure: The arrangement of atoms in a material affects how easily electrons can traverse the material. Crystalline structures, with their ordered arrangements, generally offer less resistance than amorphous structures.

-

Temperature: While temperature is a separate factor discussed later, it significantly impacts the electron mobility and thus the resistivity of the material itself.

Common Materials and Their Resistivities

Understanding the resistivity of common materials used in wire production is crucial. Here's a table showcasing the resistivity of some popular materials at room temperature:

| Material | Resistivity (Ω·m) at 20°C |

|---|---|

| Silver | 1.59 x 10⁻⁸ |

| Copper | 1.68 x 10⁻⁸ |

| Gold | 2.44 x 10⁻⁸ |

| Aluminum | 2.82 x 10⁻⁸ |

| Tungsten | 5.6 x 10⁻⁸ |

| Nichrome | 1.0 x 10⁻⁶ |

| Silicon (pure) | 2.3 x 10³ |

This table illustrates why copper is widely preferred for electrical wiring: its excellent conductivity and relatively low cost make it an ideal choice. However, other materials, such as aluminum (lighter but with slightly higher resistivity) and specialized alloys like Nichrome (high resistance, used in heating elements), are employed in specific applications based on their unique properties.

2. Length (L): The Longer, the Higher the Resistance

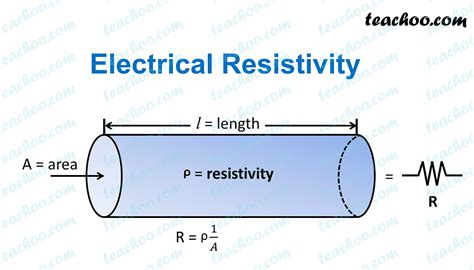

The length (L) of a wire is directly proportional to its resistance. A longer wire offers a longer path for electrons to travel, leading to more collisions with atoms and, consequently, higher resistance. This relationship is mathematically represented in the formula for resistance:

R = ρL/A

where:

- R is the resistance (in ohms)

- ρ is the resistivity of the material (in ohm-meters)

- L is the length of the wire (in meters)

- A is the cross-sectional area of the wire (in square meters)

This equation, known as the resistance formula, highlights the direct proportionality between resistance and length. Doubling the length of a wire will double its resistance, assuming all other factors remain constant.

3. Cross-Sectional Area (A): The Thicker, the Lower the Resistance

The cross-sectional area (A) of a wire is inversely proportional to its resistance. A thicker wire provides a larger area for electrons to flow, reducing the number of collisions and lowering resistance. This relationship is also evident in the resistance formula: a larger A leads to a smaller R.

Understanding Cross-Sectional Area

The cross-sectional area depends on the wire's shape, typically circular. For a circular wire, the area is calculated as:

A = πr²

where:

- A is the cross-sectional area

- π is pi (approximately 3.14159)

- r is the radius of the wire

This highlights the importance of wire gauge in electrical applications. Larger gauge wires (smaller gauge number) have larger diameters and cross-sectional areas, resulting in lower resistance.

4. Temperature (T): The Warmer, the Higher the Resistance (Usually)

Temperature significantly impacts a wire's resistivity, particularly in metallic conductors. As temperature increases, the atoms within the material vibrate more vigorously. These increased vibrations impede the free flow of electrons, leading to more collisions and increased resistance. This relationship is generally linear for many metals over a specific temperature range, and it's described by:

ρ(T) = ρ₀[1 + α(T - T₀)]

where:

- ρ(T) is the resistivity at temperature T

- ρ₀ is the resistivity at a reference temperature T₀ (often 20°C)

- α is the temperature coefficient of resistivity (a material-specific constant)

This formula indicates that resistance increases with temperature. However, it's important to note that this is a general trend; some materials, especially semiconductors, exhibit more complex relationships between resistivity and temperature.

Exceptions to the Rule

While the temperature-resistance relationship is generally positive for metals, certain materials behave differently. Semiconductors, for instance, exhibit a negative temperature coefficient of resistivity. Their resistance decreases as temperature increases because higher temperatures excite more electrons into the conduction band, increasing the number of charge carriers.

5. Impurities and Defects: A Microscopic Impact

The presence of impurities and defects within the wire's crystalline structure significantly affects its resistivity. Impurities disrupt the regular atomic arrangement, creating scattering centers for electrons and increasing resistance. Similarly, crystal defects, such as dislocations and vacancies, act as obstacles to electron flow, enhancing resistivity. This is why high-purity metals are preferred for applications requiring low resistance. The purer the metal, the fewer impurities and defects, resulting in lower resistivity.

Alloying and Its Effects

Alloying, the process of mixing different metals, is often used to tailor the properties of materials. While it can improve certain characteristics like strength and durability, it usually increases the resistivity due to the disruption of the crystal lattice caused by different atomic sizes and types. However, strategically chosen alloying elements can sometimes lead to desired changes in resistivity, making them useful in specific applications (e.g., Nichrome for heating elements).

6. Other Factors: Strain and Frequency

While the factors above are the primary determinants, other subtle influences can affect a wire's resistance:

-

Strain: Mechanical stress or strain applied to a wire can alter its atomic structure, affecting electron mobility and thus resistivity. Stretching a wire, for example, can slightly increase its resistance.

-

Frequency: At high frequencies, the skin effect comes into play. Electrons tend to flow closer to the surface of the conductor, effectively reducing the cross-sectional area available for current flow and increasing resistance. This is particularly relevant for high-frequency applications.

Conclusion: A Holistic Perspective

The resistivity of a wire isn't a simple, static property. It's a complex interplay of material characteristics, physical dimensions, temperature, and microscopic imperfections. Understanding these dependencies is crucial for selecting appropriate wires for various electrical and electronic applications. Whether designing a power transmission line, a microchip circuit, or a heating element, a thorough comprehension of how these factors influence resistance is essential for optimal design and performance. By considering the material's resistivity, wire length, cross-sectional area, temperature, and the influence of impurities and defects, engineers can accurately predict and control the resistance of electrical conductors, ensuring efficient and reliable operation of electrical systems.

Latest Posts

Latest Posts

-

A Golf Ball Is Struck At Ground Level

Mar 26, 2025

-

What Is The Derivative Of X To The X

Mar 26, 2025

-

Is Diamond An Element Compound Or Mixture

Mar 26, 2025

-

Why Did Russia Withdraw From Ww1

Mar 26, 2025

-

Thylakoids Are Arranged In Stacks Called

Mar 26, 2025

Related Post

Thank you for visiting our website which covers about The Resistivity Of A Wire Depends On . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.