Match The Organism To The Product It Produces During Fermentation.

News Leon

Mar 14, 2025 · 6 min read

Table of Contents

Match the Organism to the Product it Produces During Fermentation

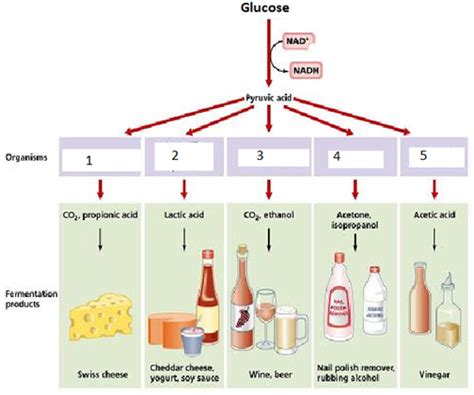

Fermentation, a metabolic process that produces chemical changes in organic substrates through the action of enzymes, is a cornerstone of various industries and crucial for numerous biological processes. Understanding which organism produces which fermentation product is key to leveraging this process effectively. This comprehensive guide will delve into the fascinating world of fermentation, matching specific organisms with their unique fermentation products. We'll explore the diverse applications of these products, from food and beverages to pharmaceuticals and biofuels.

Understanding Fermentation: A Biological Process

Fermentation is an anaerobic process, meaning it occurs in the absence of oxygen. It's an energy-releasing process where microorganisms, primarily bacteria, yeasts, and fungi, break down complex organic compounds into simpler ones. This process doesn't involve the electron transport chain, unlike aerobic respiration. Instead, organic molecules serve as both electron donors and acceptors, resulting in the production of various metabolic byproducts. These byproducts are the key products of fermentation and are often the desired outcome in industrial settings.

Key Players in Fermentation: Microorganisms

The success of fermentation hinges on the specific microorganism employed. Different organisms possess unique enzymatic capabilities, leading to the production of distinct fermentation products.

- Bacteria: Bacteria are prolific fermenters, producing a wide array of products, including lactic acid, acetic acid, ethanol, and various other organic acids.

- Yeasts: Yeasts, primarily Saccharomyces cerevisiae, are famous for their role in alcoholic fermentation, producing ethanol and carbon dioxide. However, different yeast strains can yield other products as well.

- Fungi: Certain fungi, like Aspergillus and Penicillium species, are involved in the production of various organic acids and other metabolites through fermentation.

Matching Organisms to Fermentation Products: A Detailed Guide

The following table provides a comprehensive list of microorganisms and their associated fermentation products. This list is not exhaustive but covers some of the most commonly encountered examples in various industries.

| Organism | Fermentation Product(s) | Application(s) |

|---|---|---|

| Saccharomyces cerevisiae | Ethanol, Carbon Dioxide | Alcoholic beverages (beer, wine), bread making |

| Zymomonas mobilis | Ethanol, Carbon Dioxide | Alcoholic beverages (pulque), biofuel production |

| Lactobacillus spp. | Lactic acid | Yogurt, cheese, sauerkraut, pickles, silage |

| Streptococcus spp. | Lactic acid | Yogurt, cheese, some fermented meats |

| Acetobacter aceti | Acetic acid | Vinegar production |

| Clostridium acetobutylicum | Butanol, Acetone, Ethanol | Solvent production, biofuel production |

| Propionibacterium spp. | Propionic acid, Acetic acid, Carbon Dioxide | Swiss cheese production |

| Escherichia coli | Lactic acid, Ethanol, Acetic acid, etc. | Various industrial applications, biofuel research |

| Bacillus subtilis | Various organic acids, enzymes | Food preservation, industrial enzyme production |

| Aspergillus niger | Citric acid | Food and beverage industry, pharmaceuticals |

| Penicillium spp. | Various organic acids, antibiotics | Cheese production, pharmaceuticals |

Detailed Analysis of Key Organisms and Products

Let's delve deeper into some key organisms and the intricacies of their fermentation processes:

1. Saccharomyces cerevisiae and Alcoholic Fermentation: This yeast species is the workhorse of alcoholic fermentation, converting sugars (glucose, fructose, sucrose) into ethanol and carbon dioxide. The process involves a series of enzymatic reactions, ultimately leading to the production of the desired alcoholic beverage or leavened bread. Different strains of S. cerevisiae are employed depending on the desired characteristics of the final product, influencing factors like alcohol content, flavor profile, and aroma.

2. Lactobacillus spp. and Lactic Acid Fermentation: Various species of Lactobacillus bacteria are responsible for the production of lactic acid during fermentation. This process is crucial for the production of yogurt, cheese, sauerkraut, pickles, and silage. Lactic acid bacteria (LAB) contribute not only to the characteristic sour taste but also to the preservation of these foods by lowering the pH and inhibiting the growth of spoilage microorganisms. The specific species of Lactobacillus used determines the final product's characteristics, influencing flavor, texture, and shelf life.

3. Acetobacter aceti and Acetic Acid Fermentation: Acetobacter aceti is a bacterium that converts ethanol to acetic acid, the key component of vinegar. This process, known as acetic acid fermentation, typically involves a two-step process: first, the conversion of sugars to ethanol by yeast, followed by the oxidation of ethanol to acetic acid by Acetobacter aceti. The production of high-quality vinegar depends on carefully controlled conditions, including oxygen availability and temperature.

4. Clostridium acetobutylicum and Solventogenesis: This bacterium is unique for its ability to produce a mixture of solvents during fermentation, including butanol, acetone, and ethanol. This process, known as solventogenesis, occurs under specific conditions and is of interest for its potential applications in biofuel production. The ability to produce butanol, a superior biofuel compared to ethanol in terms of energy density and compatibility with existing infrastructure, makes C. acetobutylicum a promising organism for sustainable energy research.

5. Aspergillus niger and Citric Acid Production: Aspergillus niger, a fungus, is widely used in the industrial production of citric acid. The process involves submerged fermentation, where the fungus is grown in a liquid medium containing sugars. The optimal conditions for citric acid production are carefully controlled to maximize yield and minimize the production of other unwanted byproducts. Citric acid finds wide application in the food and beverage industry, as a flavor enhancer, preservative, and chelating agent.

Applications of Fermentation Products

The products of fermentation have numerous applications across various sectors:

1. Food and Beverage Industry: Fermentation is fundamental to the production of countless food and beverages. Yogurt, cheese, bread, beer, wine, vinegar, sauerkraut, pickles – these are just a few examples. Fermentation not only enhances flavor and texture but also extends shelf life and improves nutritional value by increasing the bioavailability of certain nutrients.

2. Pharmaceuticals: Fermentation plays a vital role in the production of various pharmaceuticals, including antibiotics (penicillin, streptomycin), vitamins (vitamin B12), and other bioactive compounds. Many pharmaceuticals are derived from microbial metabolites produced during fermentation.

3. Biofuels: The production of biofuels, such as ethanol and butanol, is an increasingly important application of fermentation. Microbial fermentation provides a renewable and sustainable alternative to fossil fuels, reducing our reliance on non-renewable energy sources.

4. Industrial Applications: Fermentation is used in the production of various industrial chemicals, enzymes, and solvents. These compounds find diverse applications in various manufacturing processes.

5. Waste Treatment: Fermentation can be employed in waste treatment processes to break down organic waste, reducing environmental pollution and producing valuable byproducts.

Future of Fermentation: Innovation and Sustainability

Fermentation technology is constantly evolving, with ongoing research focusing on enhancing productivity, optimizing processes, and developing novel applications. The use of genetic engineering and metabolic engineering techniques allows for the development of microorganisms with enhanced fermentation capabilities, leading to higher yields and the production of new products. Furthermore, the focus on sustainable fermentation processes, using renewable resources and minimizing environmental impact, is crucial for a future where fermentation plays an even greater role in meeting global needs. This includes the exploration of alternative substrates for fermentation, such as agricultural waste and industrial byproducts.

The field of fermentation is dynamic and holds immense potential for innovation. By understanding the diverse array of microorganisms and their respective fermentation products, we can harness the power of this ancient process to create a more sustainable and prosperous future. The continued exploration and development of fermentation technology will undoubtedly lead to new discoveries and advancements, impacting various aspects of our lives.

Latest Posts

Related Post

Thank you for visiting our website which covers about Match The Organism To The Product It Produces During Fermentation. . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.