Face Centered Cubic Unit Cell Coordination Number

News Leon

Apr 06, 2025 · 6 min read

Table of Contents

Face-Centered Cubic (FCC) Unit Cell: A Deep Dive into Coordination Number and Crystal Structure

The face-centered cubic (FCC) unit cell is a fundamental building block in crystallography, representing the arrangement of atoms in many important metals and alloys. Understanding its structure, particularly its coordination number, is crucial for comprehending material properties like density, ductility, and electrical conductivity. This comprehensive article will delve into the intricacies of the FCC unit cell, focusing on its coordination number and its implications.

Understanding the FCC Unit Cell Structure

The FCC unit cell is a cubic arrangement where atoms are located at each of the eight corners of the cube and at the center of each of the six faces. This arrangement differs from the simpler body-centered cubic (BCC) structure, which has an additional atom at the very center of the cube.

Key Features of the FCC Structure:

-

Atoms per Unit Cell: While there are 8 corner atoms and 6 face-centered atoms, each corner atom is shared by eight adjacent unit cells, contributing only 1/8 of an atom to the unit cell. Each face-centered atom is shared by two adjacent unit cells, contributing 1/2 an atom to the unit cell. Therefore, the total number of atoms per FCC unit cell is (8 x 1/8) + (6 x 1/2) = 4 atoms.

-

Atomic Packing Factor (APF): The APF represents the fraction of the unit cell volume occupied by atoms. In an FCC structure, the APF is remarkably high at approximately 0.74. This high packing efficiency contributes to the high density observed in many FCC metals. It indicates that atoms are closely packed together, leaving minimal empty space.

-

Lattice Parameter: The lattice parameter, often denoted as 'a', represents the length of one side of the unit cell. This parameter is crucial for calculations related to unit cell volume, interatomic distances, and other material properties.

-

Symmetry: The FCC unit cell exhibits high symmetry, possessing several planes and axes of symmetry. This high symmetry influences the material's physical and mechanical properties.

Coordination Number in FCC: A Detailed Explanation

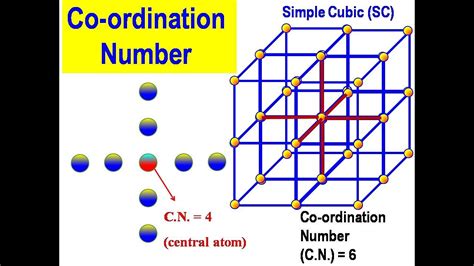

The coordination number in a crystal structure refers to the number of nearest-neighbor atoms surrounding a central atom. This number is a fundamental characteristic that significantly impacts the material's properties. Determining the coordination number requires visualizing the arrangement of atoms within the unit cell and its immediate surroundings.

Determining the Coordination Number in FCC:

Consider a single atom within an FCC unit cell. Let's focus on an atom at a corner of the cube. This corner atom has 12 nearest neighbors:

- 6 face-centered atoms: The atom is directly adjacent to six atoms located at the centers of the faces of the unit cell.

- 6 corner atoms: It's also directly adjacent to six atoms located at the corners of the neighboring unit cells. These are not part of the original unit cell.

Similarly, if we consider a face-centered atom, it has 12 nearest neighbors as well. Therefore, regardless of which atom we choose in the FCC unit cell, the coordination number consistently remains 12.

Implications of the Coordination Number (12) in FCC Structures

The coordination number of 12 in FCC structures has profound implications for the resulting material properties:

-

High Density: The high coordination number leads to a closely packed structure, resulting in high density materials. Many metals with FCC structures, like copper, aluminum, and gold, exhibit relatively high densities compared to materials with other crystal structures.

-

Ductility and Malleability: The close packing and symmetrical arrangement of atoms make FCC metals highly ductile and malleable. These materials can be easily deformed under stress without fracturing, making them suitable for applications requiring formability, such as sheet metal forming and wire drawing. The ability of atoms to slide past each other along close-packed planes contributes to this property.

-

Electrical Conductivity: The close proximity of atoms and the relatively free movement of valence electrons contribute to the high electrical conductivity observed in many FCC metals. The electron cloud can easily move through the crystal lattice facilitating the flow of current.

-

Slip Systems: The FCC structure possesses multiple slip systems, which are planes and directions along which dislocations can move. This high number of slip systems contributes to the material's ductility and work hardenability. The ease of dislocation movement leads to plastic deformation rather than fracture.

-

Stacking Fault Energy: FCC materials typically have relatively low stacking fault energy. Stacking faults are imperfections in the stacking sequence of atomic planes. The low stacking fault energy allows for extended stacking faults, influencing the mechanical properties of the material.

Comparing FCC to Other Crystal Structures

To fully appreciate the uniqueness of the FCC structure and its coordination number, let's compare it to other common crystal structures:

-

Body-Centered Cubic (BCC): The BCC structure has a coordination number of 8. This lower coordination number leads to a lower atomic packing factor (0.68) compared to FCC, resulting in lower density and different mechanical properties. BCC metals are generally stronger but less ductile than FCC metals.

-

Hexagonal Close-Packed (HCP): Similar to FCC, the HCP structure has a high atomic packing factor (0.74), also leading to a high density. However, its coordination number is also 12, but it possesses a different atomic arrangement and consequently different properties compared to FCC. HCP metals tend to be less ductile than FCC metals.

Applications of FCC Metals

Many commercially important metals exhibit an FCC crystal structure. Their unique properties, stemming directly from their coordination number and resulting atomic arrangement, lead to a wide range of applications:

-

Aluminum: Used extensively in transportation (automotive, aerospace), packaging, and construction due to its light weight, high ductility, and corrosion resistance.

-

Copper: A vital electrical conductor used in wiring, electronics, and plumbing due to its exceptional conductivity.

-

Gold: Prized for its malleability, ductility, and inertness, making it ideal for jewelry and electronic applications.

-

Nickel: Used in alloys for high-temperature applications due to its strength and corrosion resistance.

-

Silver: Another excellent electrical conductor utilized in electronics and jewelry.

-

Platinum: Used as a catalyst in many chemical processes due to its catalytic activity and resistance to corrosion.

Advanced Concepts and Further Exploration

The discussion above provides a fundamental understanding of the FCC unit cell and its coordination number. However, several advanced concepts build upon this foundation:

-

Defects in FCC Structures: Real-world materials are not perfect crystals; they contain various defects, including vacancies, interstitials, and dislocations. These defects significantly influence material properties.

-

Alloying and Solid Solutions: The properties of FCC metals can be further tailored by alloying, creating solid solutions with other elements. This process modifies the lattice parameter, electron configuration, and ultimately the mechanical and electrical properties.

-

Phase Transformations: FCC metals can undergo phase transformations under varying temperature and pressure conditions, altering their crystal structure and properties.

-

Computational Modeling: Advanced computational techniques, such as density functional theory (DFT), are used to simulate and predict the properties of FCC materials and their interactions with other materials.

This detailed exploration demonstrates the crucial role of the coordination number in defining the structure and properties of FCC materials. Understanding this concept is fundamental to material science and engineering, allowing for the design and development of materials with specific properties tailored for various applications. The high coordination number of 12, along with the close-packed arrangement, underpins the unique attributes of FCC metals making them essential in numerous technological applications. Further research into this structure and its variations will undoubtedly lead to advancements in material science and engineering.

Latest Posts

Latest Posts

-

Write A Letter For Increment Of Salary

Apr 09, 2025

-

A Material That Does Not Conduct Heat Well

Apr 09, 2025

-

Is Air A Compound Element Or Mixture

Apr 09, 2025

-

Equipotential Surfaces Associated With An Electric Dipole Are

Apr 09, 2025

-

What Is The Prime Factorization Of 234

Apr 09, 2025

Related Post

Thank you for visiting our website which covers about Face Centered Cubic Unit Cell Coordination Number . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.