Coefficient Of Linear Expansion Of Iron

News Leon

Apr 04, 2025 · 6 min read

Table of Contents

- Coefficient Of Linear Expansion Of Iron

- Table of Contents

- Coefficient of Linear Expansion of Iron: A Deep Dive

- Understanding Linear Thermal Expansion

- The Coefficient of Linear Expansion for Iron

- Practical Applications of Understanding Iron's Linear Expansion

- 1. Structural Engineering:

- 2. Manufacturing and Machining:

- 3. Material Science and Research:

- 4. Automotive Industry:

- Factors Affecting the Coefficient of Linear Expansion of Iron

- Measuring the Coefficient of Linear Expansion

- Conclusion

- Latest Posts

- Latest Posts

- Related Post

Coefficient of Linear Expansion of Iron: A Deep Dive

Iron, a ubiquitous metal fundamental to countless applications, exhibits a characteristic property known as linear thermal expansion. Understanding the coefficient of linear expansion for iron is crucial in various engineering disciplines, from structural design to material science. This comprehensive article delves into the intricacies of iron's linear expansion, exploring its theoretical underpinnings, practical applications, and influencing factors.

Understanding Linear Thermal Expansion

When a material is heated, its constituent atoms vibrate more vigorously. This increased vibrational energy leads to an expansion in the material's dimensions. Linear thermal expansion refers specifically to the change in length of a solid material in response to a change in temperature. This change is typically proportional to the original length and the temperature change.

The relationship is mathematically expressed as:

ΔL = αL₀ΔT

Where:

- ΔL represents the change in length

- α is the coefficient of linear thermal expansion (a material-specific constant)

- L₀ is the original length

- ΔT is the change in temperature

The coefficient of linear expansion (α) quantifies the fractional change in length per degree Celsius (or Kelvin) change in temperature. A higher α value indicates a greater expansion for a given temperature change.

The Coefficient of Linear Expansion for Iron

The coefficient of linear expansion for iron is not a single, fixed value. It varies depending on several factors, including:

- The specific type of iron: Pure iron, cast iron, wrought iron, and various steel alloys all possess slightly different coefficients. The presence of alloying elements significantly alters the material's microstructure and, consequently, its thermal expansion behavior.

- Temperature: The coefficient is not constant across all temperature ranges. Its value typically increases slightly with temperature. This non-linearity is often ignored for small temperature variations, but it becomes significant for large temperature swings.

- Crystallographic structure: Iron undergoes phase transitions at certain temperatures, notably at 912°C (α to γ transition) and 1394°C (γ to δ transition). These transitions are accompanied by significant changes in the crystal structure and, thus, in the coefficient of linear expansion.

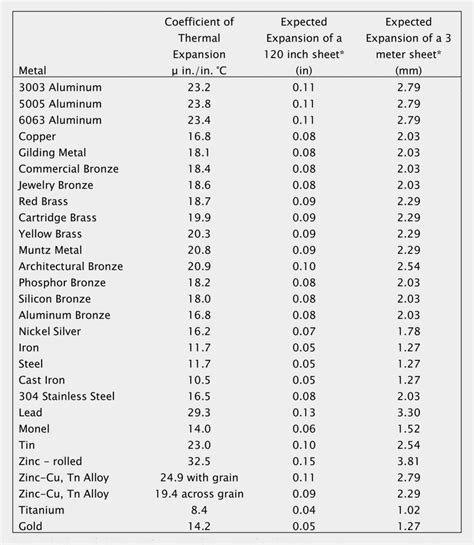

While a precise value is challenging to state without specifying the exact type of iron and temperature range, a commonly cited approximate value for the coefficient of linear expansion of iron at room temperature is 11-12 x 10⁻⁶ /°C. It’s crucial to consult material property tables for the specific type of iron being used and the relevant temperature range for the most accurate value.

Practical Applications of Understanding Iron's Linear Expansion

The knowledge of iron's coefficient of linear expansion is critical in numerous engineering applications:

1. Structural Engineering:

- Bridge Design: Bridges, particularly those made of steel (an iron alloy), experience significant temperature fluctuations. Failing to account for thermal expansion can lead to excessive stresses, potentially causing damage or failure. Expansion joints are incorporated into bridge designs to accommodate these changes in length.

- Building Construction: Similar considerations apply to tall buildings and other large structures made with iron or steel components. Thermal expansion must be factored into the design to prevent structural problems.

- Railroad Tracks: Railroad tracks expand and contract with temperature changes. Gaps are left between rails to accommodate this expansion, preventing buckling and derailments.

2. Manufacturing and Machining:

- Precision Engineering: In the manufacturing of precision parts, thermal expansion must be accounted for to ensure dimensional accuracy. The machining process itself can generate heat, affecting the final dimensions of the workpiece.

- Welding: Welding involves heating and cooling of metals. Understanding thermal expansion is crucial in preventing warping and distortion during welding processes.

- Casting: The casting process involves pouring molten iron into a mold. The cooling and solidification process involves significant temperature changes and hence, thermal expansion and contraction.

3. Material Science and Research:

- Material Characterization: Measuring the coefficient of linear expansion is a key technique for characterizing materials and investigating their microstructure.

- Alloy Development: Researchers use thermal expansion data to understand the relationship between alloy composition and material properties. This helps in developing new alloys with tailored properties for specific applications.

- Thermomechanical Processing: Thermal expansion considerations play a crucial role in optimizing thermomechanical processing techniques, which involve carefully controlling the temperature and stress during the material processing to achieve desired mechanical properties.

4. Automotive Industry:

- Engine Design: In internal combustion engines, thermal expansion of various components, including engine blocks and pistons, significantly impacts engine performance and reliability. Design engineers must consider these factors to ensure proper clearance and prevent seizing.

- Brake Systems: Thermal expansion of brake components can influence braking performance. Understanding these changes is essential for designing efficient and safe braking systems.

Factors Affecting the Coefficient of Linear Expansion of Iron

As previously mentioned, the coefficient of linear expansion of iron isn't a constant. Several factors contribute to its variability:

- Alloying Elements: Adding alloying elements to iron (e.g., carbon, chromium, nickel) alters its crystal structure and atomic bonding, directly influencing the coefficient of linear expansion. Different alloying elements have different effects, leading to a wide range of coefficients for different steel alloys. High-carbon steels typically have slightly higher coefficients compared to low-carbon steels.

- Microstructure: The microstructure of iron, including grain size and the presence of precipitates or inclusions, affects its thermal expansion behavior. Finer grain sizes generally lead to slightly lower coefficients.

- Temperature: The coefficient is temperature-dependent, particularly at higher temperatures. This non-linear relationship requires careful consideration in applications involving significant temperature variations.

- Phase Transformations: As noted earlier, iron undergoes phase transitions at specific temperatures, associated with abrupt changes in its crystal structure. These phase transitions cause significant changes in the coefficient of linear expansion.

- Internal Stresses: Residual internal stresses within the iron can influence its thermal expansion behavior. These stresses can arise from manufacturing processes like casting, rolling, or welding.

Measuring the Coefficient of Linear Expansion

The coefficient of linear expansion can be experimentally determined using several methods:

- Dilatometry: This technique involves measuring the change in length of a sample as a function of temperature. A dilatometer accurately measures the small changes in length, allowing for precise determination of the coefficient.

- Optical Interferometry: This method utilizes interference patterns of light waves to measure minute changes in length with high precision.

- X-ray Diffraction: This technique uses X-rays to analyze the crystal structure of a material at different temperatures. Changes in the crystal lattice parameters can be used to calculate the coefficient of linear expansion.

Conclusion

The coefficient of linear thermal expansion of iron is a critical property with wide-ranging implications across various engineering and scientific fields. Understanding this property and its influencing factors is crucial for designing reliable and efficient structures, manufacturing precise components, and developing new materials. While an approximate value is often cited, the specific coefficient depends on several factors, including the type of iron, temperature, and microstructure. Consult reliable material property databases for accurate values relevant to your specific application. Precise measurement techniques are employed to determine the coefficient for research and quality control purposes. The ongoing research into iron's thermal properties continues to contribute to advancements in diverse industrial applications.

Latest Posts

Latest Posts

-

5 Times A Number Increased By 8

Apr 06, 2025

-

Prime Numbers Between 40 And 50

Apr 06, 2025

-

When Does A Short Circuit Occur

Apr 06, 2025

-

Equation Of A Line Parallel To The Y Axis

Apr 06, 2025

-

E How Many Electrons Are In Mg2

Apr 06, 2025

Related Post

Thank you for visiting our website which covers about Coefficient Of Linear Expansion Of Iron . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.