A Toroid Having A Square Cross Section

News Leon

Mar 22, 2025 · 6 min read

Table of Contents

A Toroid with a Square Cross Section: A Comprehensive Analysis

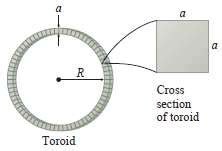

A toroid, a donut-shaped coil of wire, is a fundamental component in various electrical and electronic applications. While circular cross-section toroids are common, the analysis and design of toroids with other cross-sections, such as a square cross-section, present unique challenges and opportunities. This article delves into the intricacies of a toroid possessing a square cross-section, examining its magnetic field characteristics, inductance calculation, applications, and manufacturing considerations. We will explore both theoretical and practical aspects, providing a comprehensive understanding of this less-frequently discussed but equally important type of toroidal inductor.

Understanding the Unique Properties of a Square Cross-Section Toroid

Unlike its circular counterpart, a toroid with a square cross-section exhibits a less uniform magnetic field distribution. The sharp corners and straight edges introduce significant variations in the magnetic flux density, making the calculation of inductance more complex. This non-uniformity impacts factors such as the toroid's self-inductance, stray inductance, and susceptibility to external magnetic fields. However, the square cross-section offers potential advantages in certain applications, such as improved packaging efficiency in space-constrained designs.

Magnetic Field Distribution: A Deeper Dive

The magnetic field within a toroid with a circular cross-section is, ideally, confined entirely within the core material. This simplifies inductance calculations. However, for a square cross-section toroid, the magnetic field lines are not as uniformly distributed. They tend to concentrate near the corners, leading to higher flux density in these regions compared to the center of the square cross-section. This uneven distribution makes analytical calculations more challenging and often requires numerical methods like Finite Element Analysis (FEA) for accurate prediction.

Key Differences from Circular Cross-Section Toroids:

- Non-Uniform Field: The most significant difference lies in the non-uniformity of the magnetic field. This non-uniformity necessitates more complex mathematical models for accurate inductance calculations.

- Corner Effects: The sharp corners of the square cross-section concentrate the magnetic flux, influencing the overall magnetic field behavior.

- Increased Fringe Field: A larger fringe field, the magnetic field extending outside the toroid core, is expected compared to a circular cross-section. This fringe field can induce unwanted coupling with nearby components.

- Manufacturing Challenges: Fabricating a toroid with a precise square cross-section poses greater manufacturing challenges compared to circular cross-sections.

Calculating the Inductance of a Square Cross-Section Toroid

Calculating the inductance of a toroid, even with a simple circular cross-section, involves several factors. For a square cross-section, the complexity significantly increases. The simple formula that works well for circular cross-section toroids, L = (μ₀ * N² * A) / (2π * R), where:

- L is the inductance

- μ₀ is the permeability of free space

- N is the number of turns

- A is the cross-sectional area

- R is the mean radius

…is not directly applicable. The non-uniform field significantly affects the result. Therefore, more advanced techniques are required:

Numerical Methods for Inductance Calculation

For accurate inductance calculation of a square cross-section toroid, numerical methods are indispensable. Finite Element Analysis (FEA) is a powerful technique frequently used in electromagnetic simulations. FEA software discretizes the toroid geometry into small elements and solves Maxwell's equations numerically. This provides a detailed and accurate mapping of the magnetic field distribution and allows for precise calculation of the inductance.

Other Numerical Approaches:

- Boundary Element Method (BEM): BEM focuses on the boundaries of the problem domain, reducing the computational burden compared to FEA in certain cases.

- Finite Difference Method (FDM): FDM approximates derivatives using difference quotients, offering another numerical approach for solving Maxwell's equations.

These methods are particularly crucial when analyzing the impact of variations in the square cross-section's dimensions and material properties on the overall inductance.

Material Selection and Core Properties

The choice of core material significantly impacts the performance of the toroid inductor. Common core materials include ferrite, powdered iron, and various specialized magnetic alloys. Each material exhibits unique magnetic properties such as permeability, saturation flux density, and loss characteristics. The core material selection directly influences the inductance value, efficiency, and operating frequency range.

Key Considerations for Material Selection:

- Permeability (μ): A higher permeability material leads to higher inductance for the same number of turns and core dimensions.

- Saturation Flux Density (Bsat): The saturation flux density determines the maximum magnetic flux the core can handle before saturation occurs, leading to nonlinearity and distortion.

- Core Losses: Core losses, arising from hysteresis and eddy currents, are frequency-dependent and influence the inductor's efficiency, especially at higher frequencies.

- Temperature Stability: The material's magnetic properties should remain stable over the operating temperature range.

Choosing the appropriate core material requires careful consideration of the specific application requirements, balancing the desired inductance, saturation characteristics, and acceptable core losses.

Applications of Square Cross-Section Toroids

While circular cross-section toroids dominate many applications, square cross-section toroids find their niche in specific circumstances. Their unique shape provides advantages in certain designs:

Space-Constrained Applications

The square cross-section can lead to better space utilization in compact designs where a specific footprint is critical. This makes them suitable for miniaturized electronics, embedded systems, and applications where maximizing packaging density is paramount.

High-Power Applications (with careful design):

While the non-uniform field necessitates careful design and analysis, square cross-section toroids could be considered for high-power applications where efficient heat dissipation is crucial. The increased surface area compared to a circular toroid of the same cross-sectional area can facilitate better heat transfer. However, the design needs to meticulously address the potential for increased flux density at the corners, potentially leading to localized saturation and increased losses.

Specialized Electromagnetic Applications

The unique field distribution of a square cross-section toroid can be leveraged in specialized electromagnetic applications where a particular field profile is desired. This might involve applications in sensors, actuators, or specific magnetic shielding configurations. However, such applications often necessitate detailed FEA modeling and careful design optimization.

Manufacturing Considerations and Challenges

Manufacturing a toroid with a precise square cross-section presents significant challenges compared to circular cross-sections. Traditional winding techniques might prove inadequate, requiring specialized methods.

Manufacturing Techniques:

- CNC Machining: Precise machining from a solid block of core material ensures accurate dimensions but can be costly and time-consuming.

- Powder Metallurgy: Compressing and sintering magnetic powder can create a near-net shape, requiring less machining but potentially leading to some dimensional variations.

- Injection Molding (for plastic cores): If a non-magnetic core material (such as plastic) is acceptable, injection molding offers high-volume, cost-effective production of complex shapes.

- 3D Printing: Additive manufacturing techniques like 3D printing offer design flexibility, but material selection and dimensional accuracy remain critical concerns.

Careful consideration of manufacturing limitations is crucial in designing a square cross-section toroid, balancing the desired precision and cost-effectiveness. The manufacturing method should be selected based on factors like volume requirements, precision needs, and budget constraints.

Conclusion: Navigating the Complexities of Square Toroids

A toroid with a square cross-section represents a fascinating engineering challenge. While the non-uniform magnetic field complicates inductance calculations and necessitates advanced numerical methods like FEA for accurate analysis, its unique properties can offer advantages in specific applications, particularly where compact packaging and precise control of certain magnetic field aspects are required. Careful consideration of material selection, manufacturing limitations, and advanced simulation techniques is paramount in the successful design and implementation of this less-common type of toroidal inductor. The increased complexity doesn't negate its potential; rather, it highlights the need for a more nuanced and sophisticated approach to its design and application. Further research and development in the manufacturing and characterization techniques will further unlock the potential of square cross-section toroids in various applications.

Latest Posts

Latest Posts

-

How Many Km Is 1 7 Miles

Mar 22, 2025

-

Ode To The West Wind Meaning

Mar 22, 2025

-

How Many Kilograms In 5000 Grams

Mar 22, 2025

-

Which Phase Of The Cardiac Cycle Is The Longest

Mar 22, 2025

-

The Energy Currency Used By Cells Is

Mar 22, 2025

Related Post

Thank you for visiting our website which covers about A Toroid Having A Square Cross Section . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.