A Cylinder With A Movable Piston

News Leon

Mar 20, 2025 · 6 min read

Table of Contents

A Cylinder with a Movable Piston: Exploring its Applications and Principles

A cylinder with a movable piston is a fundamental mechanical device with a wide array of applications across various industries. From the internal combustion engine powering our vehicles to hydraulic systems lifting heavy loads, this seemingly simple apparatus forms the backbone of numerous complex machines. Understanding its workings, variations, and applications is crucial for anyone interested in engineering, mechanics, or related fields. This comprehensive article delves into the intricacies of this essential component, exploring its principles, applications, and variations.

The Fundamental Principles: How it Works

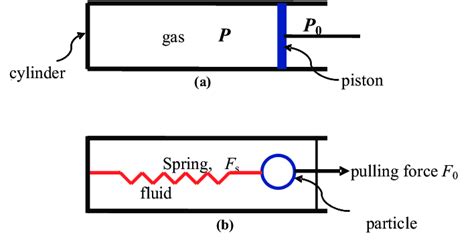

At its core, a cylinder with a movable piston is a closed system where a piston moves within a cylindrical chamber. The piston's movement is controlled by pressure differences within the cylinder, often involving gases or liquids. Several key principles govern its operation:

1. Pressure and Volume Relationship:

The most fundamental principle governing a cylinder with a movable piston is the relationship between pressure (P), volume (V), and temperature (T) of the enclosed gas or liquid. This relationship is often described by the Ideal Gas Law (PV = nRT) for ideal gases, although real-world applications often require more complex equations of state to account for non-ideal behavior. Changes in pressure will directly influence the piston's position. An increase in pressure pushes the piston outward, while a decrease in pressure allows the piston to move inward or be pulled inward by external forces.

2. Force and Pressure:

The force exerted by the gas or liquid on the piston is directly proportional to the pressure and the area of the piston. Force (F) = Pressure (P) x Area (A). This means a larger piston area will generate a greater force for the same pressure. This principle is extensively used in hydraulic systems to amplify force.

3. Mechanical Advantage:

The cylinder and piston system can provide mechanical advantage, allowing the application of a smaller force to move a larger load. This is achieved by varying the piston area in a hydraulic system. A small piston with high pressure can exert a large force on a larger piston with lower pressure.

Variations and Types of Cylinder and Piston Systems

While the basic principle remains consistent, several variations exist, each tailored to specific applications:

1. Single-Acting Cylinders:

In a single-acting cylinder, the piston moves in only one direction due to pressurized fluid. The return stroke relies on gravity, springs, or an external force. These are commonly used in simpler applications where the return stroke doesn't require precise control. Examples include some types of pneumatic door closers.

2. Double-Acting Cylinders:

These cylinders allow for bidirectional movement. Pressurized fluid is applied to either side of the piston, controlling its movement in both directions. This provides more precise and controlled movement, making them suitable for complex machinery and automation systems. Hydraulic presses and actuators in robotics frequently utilize double-acting cylinders.

3. Hydraulic Cylinders:

These cylinders use incompressible liquids, typically oil, to transmit force. Hydraulic cylinders are known for their high force output and ability to handle heavy loads. They are extensively used in construction equipment, heavy machinery, and industrial automation.

4. Pneumatic Cylinders:

Pneumatic cylinders utilize compressed air as the working fluid. They are generally lighter, faster, and cheaper than hydraulic cylinders but offer lower force output. Pneumatic cylinders are commonly found in automation systems, robotic arms, and factory machinery where speed and precision are important.

5. Rotary Cylinders:

These cylinders convert linear motion into rotary motion, and vice-versa, making them useful in applications requiring rotational movement. They are commonly used in industrial automation and robotics.

Applications across Diverse Industries

The versatility of cylinders with movable pistons is evident in their extensive applications across diverse industries:

1. Internal Combustion Engines:

The quintessential example lies within internal combustion engines, where the piston's reciprocating motion converts the explosive force of burning fuel into rotational motion, powering vehicles, generators, and machinery. The combustion cycle itself relies on the pressure changes within the cylinder.

2. Hydraulic Systems:

Hydraulic cylinders form the backbone of numerous hydraulic systems, found in everything from construction equipment (excavators, cranes) to industrial presses, and even aircraft control systems. Their ability to generate immense force and controlled movement is invaluable in these applications.

3. Pneumatic Systems:

Pneumatic cylinders play a crucial role in automation systems, robots, and manufacturing processes. Their speed and relatively simple control mechanisms make them ideal for automated tasks such as assembly, packaging, and material handling.

4. Automotive Applications:

Beyond internal combustion engines, cylinders and pistons are used in power steering systems, braking systems, and various other automotive components.

5. Manufacturing and Industrial Automation:

These systems are ubiquitous in manufacturing plants, offering precise control and repeatable movements in various automated processes. They are essential for tasks ranging from welding and painting to assembly and packaging.

6. Aerospace and Defense:

The controlled movement and force provided by cylinders and pistons are crucial in many aerospace and defense applications. Examples include flight control systems, landing gear, and ejection seats.

7. Medical Equipment:

Certain medical devices utilize hydraulic or pneumatic cylinders for controlled movement and precise positioning, examples including surgical robots and other medical equipment.

Factors Affecting Performance and Design Considerations

Several factors significantly influence the performance and design of a cylinder with a movable piston:

1. Seal Design:

Effective sealing is crucial to prevent leaks and maintain pressure. The design and material of the seals are critical for performance and longevity, requiring careful consideration based on the working fluid and pressure.

2. Rod Design:

The piston rod must withstand significant forces and stresses. Its diameter, material, and surface finish are crucial factors impacting its strength and durability.

3. Cylinder Material:

The cylinder material must be strong enough to withstand the internal pressure and external forces. The choice of material depends on factors like pressure, temperature, and the working fluid.

4. Piston Design:

The piston design affects its sealing efficiency, movement smoothness, and overall performance.

5. Cushioning:

In many applications, cushioning mechanisms are incorporated at the ends of the cylinder's stroke to reduce impact forces and prevent damage to the system.

Maintenance and Troubleshooting

Regular maintenance is critical for the long-term performance and reliability of a cylinder with a movable piston system. This includes:

- Regular inspection: Checking for leaks, damage to seals, and wear on the piston rod.

- Lubrication: Proper lubrication ensures smooth operation and reduces wear.

- Seal replacement: Replacing worn or damaged seals is essential to prevent leaks.

- Troubleshooting: Addressing issues such as leaks, lack of movement, or unusual noises can prevent major problems.

Future Trends and Innovations

Ongoing research and development continue to improve the performance, efficiency, and applications of cylinders with movable pistons:

- Advanced materials: The use of advanced materials, such as composites and high-strength alloys, is leading to lighter, stronger, and more durable components.

- Improved sealing technologies: Innovations in seal design are improving sealing efficiency, reducing leaks, and extending the lifespan of cylinders.

- Smart cylinders: The integration of sensors and actuators is transforming cylinders into "smart" devices, allowing for real-time monitoring and control.

- Miniaturization: The development of smaller, more compact cylinders is expanding their applications in micro-robotics and other miniature systems.

In conclusion, the cylinder with a movable piston remains a fundamental and versatile mechanical device with countless applications across various industries. Understanding its principles, variations, and applications is vital for anyone working with machinery, automation, or related fields. Its enduring relevance and ongoing innovation ensure its continued importance in shaping the technological landscape.

Latest Posts

Latest Posts

-

Which Three Dimensional Figure Is Formed By The Rotation Given

Mar 21, 2025

-

75 Percent Of What Number Is 15

Mar 21, 2025

-

Time Magazine Person Of The Century 1999

Mar 21, 2025

-

Ground State Electron Configuration For Titanium

Mar 21, 2025

-

Which Of The Following Is The Most Acidic

Mar 21, 2025

Related Post

Thank you for visiting our website which covers about A Cylinder With A Movable Piston . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.